Onshape is offering hardware startups and entrepreneurs free access to Onshape Professional or Onshape Government (compliant with ITAR/EAR). Both include CAD, rendering, simulation, PDM, and more. Apply for the program to get started today.

Interesting Links 🏭

A closer look at how waterproofing really works, through carefully designed rubber interfaces in plastic and metal housings. Waterproofing (and airtight sealing) sounds glamorous, but in practice the most common solution comes down to compressing an O-ring into a groove; typically 10–40% for static applications and 10–30% for dynamic (moving) ones. There are three main sealing types: face seals (simple, static, less precise), radial seals (precise, good for high-pressure), and crush seals (deformable hybrids). For mission-critical builds like deep sub-sea or aerospace systems, it's common to stack a crush seal behind a primary one. Material choice depends on the environment where nitrile is a common option, while silicone is used in high-temperature applications. The real work is in groove design where features (depth, width, surface finishes, etc.) of touching interfaces must all be tightly controlled depending on the application and sealing type. For extra reading, Parker’s O-Ring Handbook is a classic and Fiveflute’s writeup includes information on gasket sealing strategies.

Moravec's paradox is the observation that tasks easy for humans, like walking or performing motor/sensory skills, are extremely difficult for AI while tasks that are hard for humans, like complex math or chess, are relatively easy for AI to perform. In robotics, the same paradox shows up as more humanoids are trained to perform increasingly acrobatic tasks like backflips (see Unitree's demo) while still struggling with basic object manipulation. Nvidia’s Head of Robotics recently went on record saying “it’s much easier to train a ‘blind gymnast’ than a robot that sees and manipulates. The former can be solved entirely in simulation and transferred zero-shot to the real world, while the latter demands extremely realistic rendering, contact physics, and messy real-world object dynamics - none of which can be simulated well.”

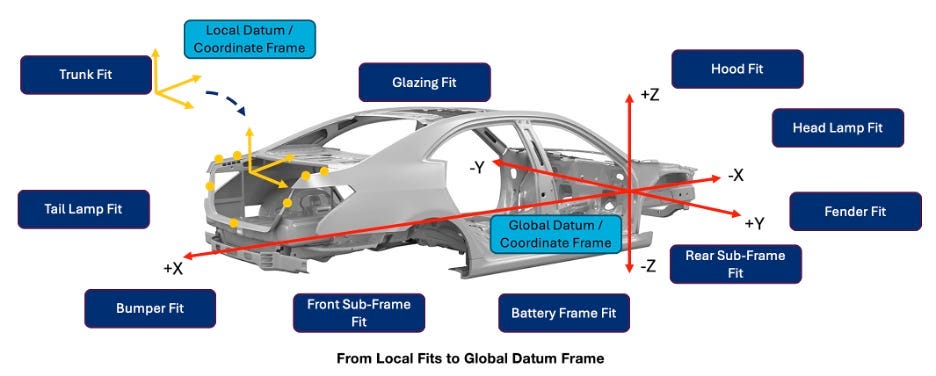

From Glenn Turley at WattFactory, one of the clearest explanations of tolerance analysis and statistical process control set in the context of automotive body alignment. A classic example dates back to early Model 3 production at Tesla, where inconsistent panel gaps were an outcome of misaligned local datums across global assemblies. He boils it down to three essentials: lock in a global datum and let local datums cascade so sub‑assemblies mate cleanly; run tolerance stacks - worst‑case for safety‑critical joints, and root sum squared for everything else to see how variation really adds up; and use statistical process control (SPC) to monitor key features to capture tolerance drift before it hits final assembly.

Some quick definitions: datums are reference features that anchor parts in space, tolerance stacks analyze how variation builds up across parts, and SPC monitors variation in key features to ensure the process stays within spec.

“Just as tributaries flow into the Amazon or Nile, there are sub-datum schemes that feed into this global structure.” Each one “has its own local assembly process and datum cascade until it converges with the main river.”

In one of the more remarkable recent demos in human–computer interaction, Meta unveiled a wrist-worn wearable that uses surface electromyography (sEMG) sensors to decode and generalize subtle finger twitches into precise inputs like typing full sentences in mid-air, or even cursive handwriting. At a high-level, the system uses 48 dry sEMG electrodes sampling at 2 kHz with sub-3 µV noise to capture muscle signals at the wrist. The real unlock came from training on the largest sEMG dataset to date: thousands of users performed structured motion that enabled generalization across users with no calibration. Personalization with ~10 minutes of data gives ~16% faster performance, but the base model already works cross-user. Full paper here.

Apparently automatic fastener detection is a built-in feature for standard CAD packages like SolidWorks, where users can drag and drop hardware like nuts, bolts, and washers into the CAD window and software automatically mates them into hole patterns sized for standard fasteners. There’s not much technical detail published on how it works, but based on past patents (i, ii) it works by scanning the model for cylindrical hole geometry (especially linear or circular patterns) and matching those features to known fastener sizes in the Toolbox database. Once identified, it inserts the correct stack and applies concentric and coincident mates based on surrounding faces.

A couple fun links:

A reader surfaced rare footage of Hughes Aircraft’s automated machining line from 1958, one of the first CNC shops running on punch-tape instructions.

This week in wearable electronics, resistor earrings.

A classic shot of Space Shuttle Endeavour’s farewell tour in 2012, piggybacked on a 747 during its retirement flyover.

We still have limited space for our SF Hardware Happy Hour in late August (8/28). Free foods, free drinks and good people to talk shop - check it out here.

Presented by First Resonance: Rethinking Factory Intelligence

Traditional automation struggles to keep pace with modern production demands. This new eBook, The Agentic Shift: Building Intelligence Into the Fabric of Industry, explores how forward-thinking manufacturers are moving beyond dashboards and static scripts to agentic systems that sense, decide, and adapt in real time. The free guide offers a practical framework for building smarter, more resilient operations powered by AI agents.

Download your copy and start shaping the future of manufacturing.

Startup News 🚀

Nudge raised $100M in Series A funding to advance development of its non-invasive focused ultrasound brain interface. The platform aims to safely stimulate and image the brain with millimeter precision without any surgery required. Their system combines advanced ultrasound hardware, real-time signal processing, and closed-loop feedback to deliver targeted brain modulation through the skull. Thrive Capital and Greenoaks led the round.

Syncere came out of stealth introducing Lume, a robotic lamp designed to assist with daily chores starting with laundry folding. The team is taking a different approach from humanoid robots, exploring a non-anthropomorphic form factor with a set of two robotic arms that double as stationary lights when not in use. The company is targeting a summer 2026 launch, though no working prototypes have been shown beyond a playful demo.

Diode Computers raised $11.4M in a Series A funding round to accelerate custom PCB development with AI. Their software replaces traditional schematic tools with a code-based workflow, using LLMs and reinforcement learning to generate layouts and reconfigure designs. Andreessen Horowitz led the funding.

Bonsai Robotics acquired farm-ng to expand its autonomous farming capabilities with a full-stack hardware and software solution. The integration pairs Bonsai’s vision-based AI autonomy with farm-ng’s modular electric Amiga robot, enabling operation in environments without GPS or other global navigation satellite systems (GNSS). The combined platform targets rugged, customizable crop management for small to mid-sized farms. Terms were not disclosed.

Cascade Space raised a $5.9M seed round to accelerate development of Cascade Portal, its platform for satellite communication system design, test, and operation. The company recently open-sourced spacelink, a Python library used in the Portal for communication system analysis. The tools aim to reduce engineering bottlenecks in mission planning, particularly for lunar and deep space applications. The round was led by Nova Threshold and Undeterred Capital.

Firestorm Labs raised $47M in Series A funding to scale its additive manufacturing platform for modular drone production. The company's xCell system is a mobile, modular 3D-printing unit designed to produce UAS airframes and components at the point of need. New Enterprise Associates led the funding, including $12M in venture debt from J.P. Morgan.

Open Jobs 💼

More jobs added weekly on our job board. If you're hiring, promote your open role here.

Sponsored:

Rainmaker is hiring a Robotics Engineer to design and deploy modern cloud seeding systems in El Segundo, CA

Early Career:

Tesla is looking for a Mechanical Design Analysis Engineer in Fremont, CA

Mid-Level:

Open AI is looking for a Hardware System Design Electrical Engineer & Firmware Engineer (Robotics) in San Francisco, CA

Bose is looking for an Engineering Program Manager (Audio) in Framingham, MA

Senior to Staff:

Graymatter Robotics is looking for a Director of Hardware in Gardena, CA

Doordash Labs is looking for a Technical Program Manager in San Francisco, CA

Internships:

Contoro Robotics is looking for a Robotics Engineering Intern (Fall) in Austin, TX

Tools From Our Sponsors

Manufacturing

Loombotic - Instant-quote custom wire harnesses. Upload drawings or design online, fast turnaround.

Summit Interconnect – Quick-turn complex rigid, flex, and rigid-flex PCBs.

Fictiv – On-demand custom manufacturing from prototype to production.

Formlabs Fuse – Office-ready SLS printer for in-house nylon production with industrial part quality.

Design & Simulation

Quilter – Fully automates PCB layout with physics-driven AI.

nTop – Computational design to accelerate product development.

Onshape – Cloud CAD with real-time collaboration and version control.

Dystr – AI math environment that slashes analysis time 10–100×.

Ops & Collaboration

Dirac – Work instructions, automated. Context-aware production planning starts here.

Doss – Adaptive ERP for orders, inventory, and production.

AllSpice – Git-style revision control for hardware designs.

If you're prepping for interviews, we've put together practical resources for engineers. For all resources available, check our home page.

Access Every Link We’ve Ever Shared 🎞️

Refer three friends to Hardware FYI and unlock our full archive.

Missed an issue? Hunting for that one link? Every tool, guide, and article we’ve ever shared is in here.

Thank you for sharing and spreading the word on tolerance stacks. Also, I have just downloaded the Agentic Shift, it looks like a great resource for those interested in how AI will transform manufacturing!