Today’s Menu: 🍚

Open Jobs

NFL Helmet’s Brittle Fracture

Apple Vision Pro Manufacturing Process

Question of the Week - Communication Protocols

Open Jobs 💼

Internships

Nvidia is hiring a hardware verification intern in Santa Clara, CA

Astranis is hiring a propulsion engineering intern in San Francisco, CA

Intel is hiring a manufacturing engineering intern in Phoenix, AZ

Full-Time

Calvary Robotics is hiring a robotics engineer in Webster, NY

Amazon is hiring a hardware development engineer in Bellevue, WA

Blue Origin is hiring a senior software engineer in Seattle, WA

Lucid is hiring a senior electrical engineer in Southfield, MI

Tackling Brittle Fracture in NFL Helmets 🏈

On January 13th, the Kansas City Chiefs played against the Miami Dolphins in temperatures around -4℉, making it one of the coldest games in NFL history. This wasn't just any game—it became a historic marker for one of the NFL's coldest battles ever waged. But the real game-changer? Patrick Mahomes' helmet shattering upon impact.

Football helmets are typically made from polycarbonate, a thermoplastic whose impact strength reduces with lowered temperature as it becomes more brittle. To understand this, envision polymers as long, spaghetti-like molecular strands, entangled yet flexible. This flexibility is due to the ability of these strands to move and slide over each other when warm. However, in colder conditions, polymers experience a 'glass transition,' shifting from a rubbery to a more rigid, glass-like state. This transformation renders the helmet more vulnerable to impact, a factor likely contributing to its failure during a head-to-head collision in a cold environment.

Some of this oversight could be due to materials being optimized for expected conditions. For example, ice hockey helmets are typically made of high-density polyethylene which has a lower glass-transition temperature.

Given that other helmets used that night remained intact, the underlying reason is probably a mix of several elements, such as the point of impact and specific helmet characteristics.

Apple Vision Pro Manufacturing Process 🥽

Apple recently released a behind the scenes video that outlines manufacturing steps for the aluminum frame of their augmented reality headset. This peek behind the scenes fuels a fascination I've nurtured ever since diving into Ben Einstein’s post about the contrasts in manufacturing approaches between start-ups and large companies.

For Apple, it's a landscape where conventional wisdom often takes a back seat and the company drives in a lane almost of its own making. With the launch of the Vision Pro, Pete Oxenham’s breakdown of their manufacturing steps proves to be the perfect example.

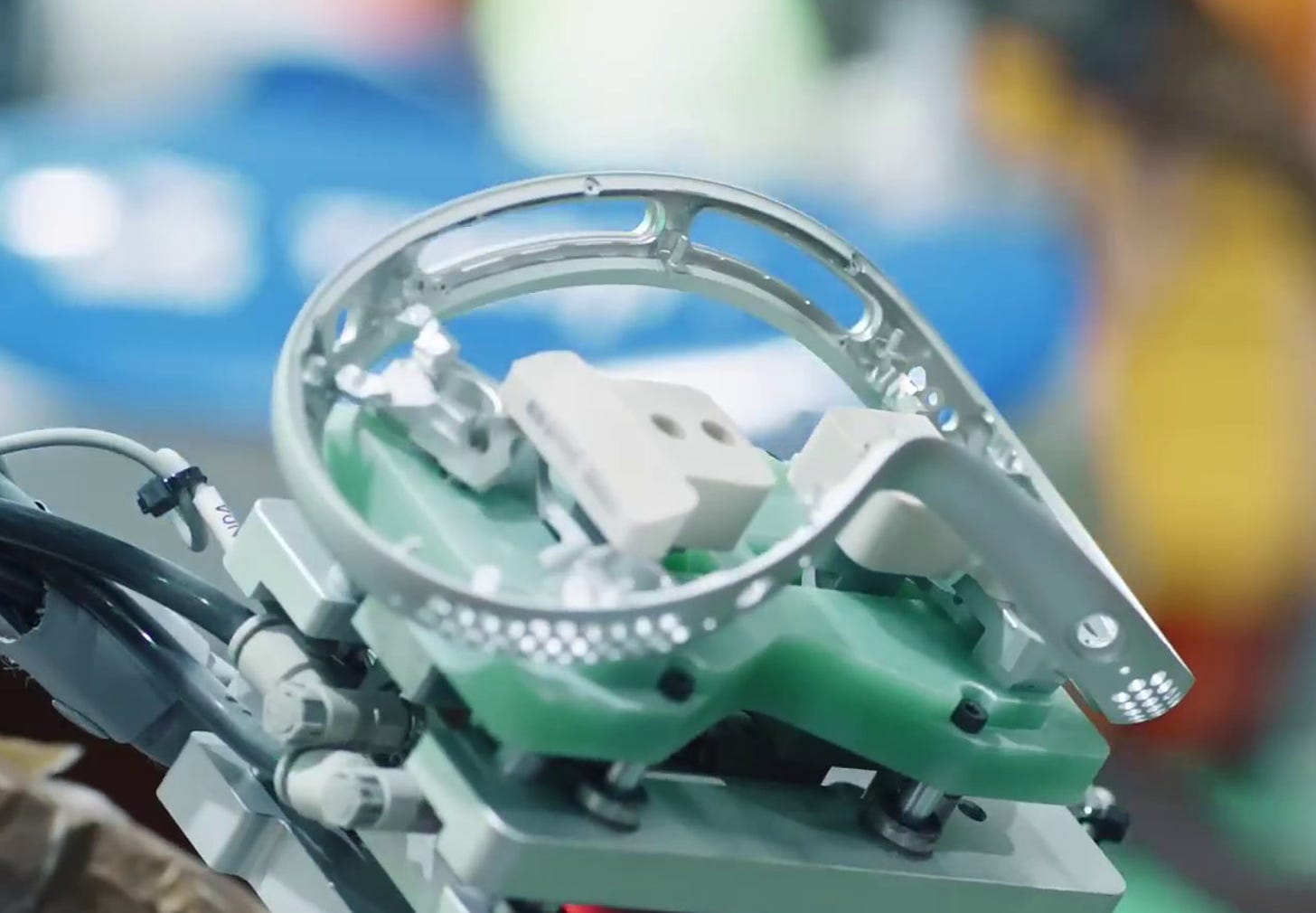

To produce the frame of the headset, the machining steps are:

Molten aluminum is extruded through a die with the cross-section below:

The bars are cut using a saw into their proper lengths.

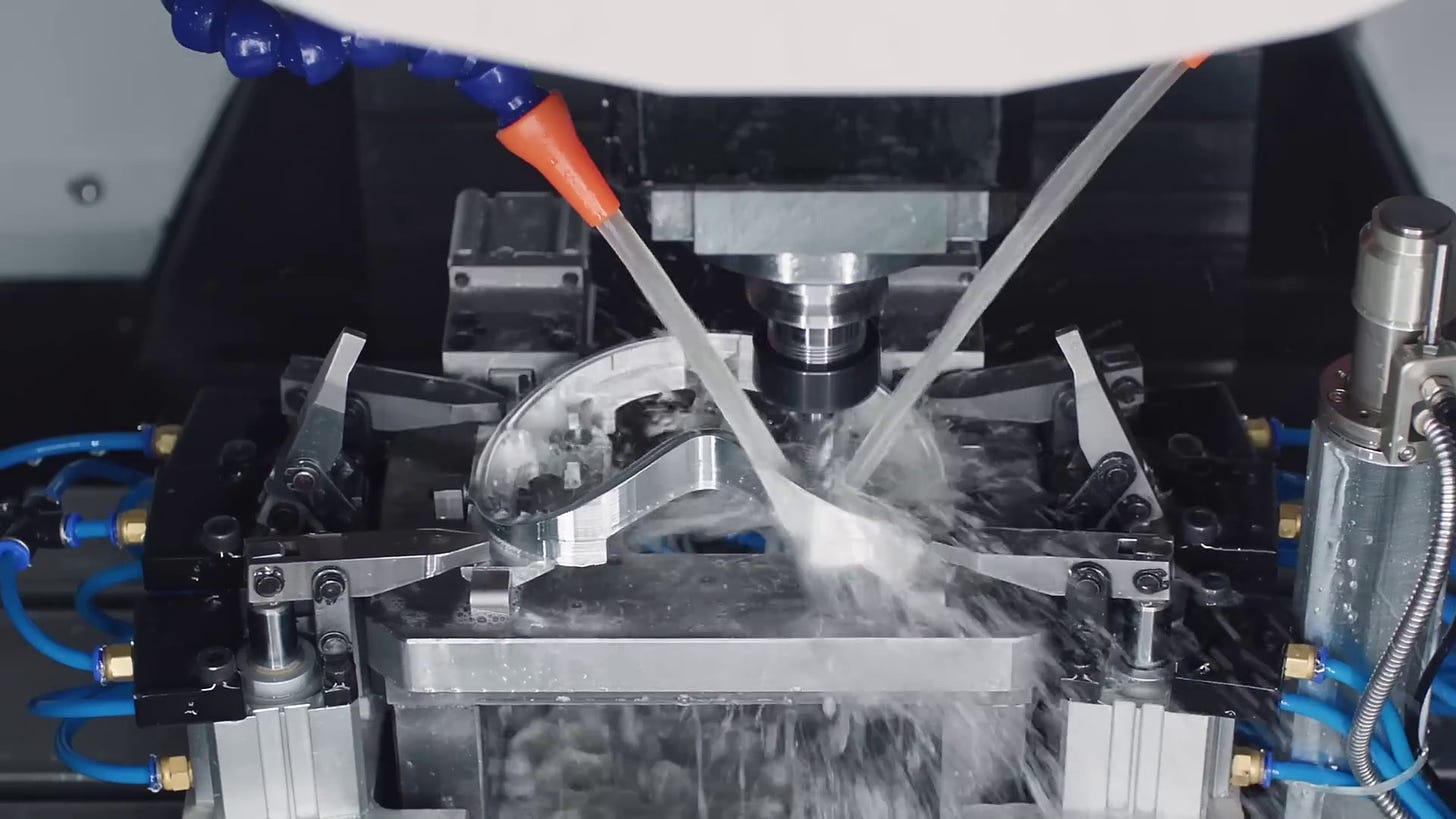

A 3-axis mill begins to cut out its shape along with alternating clamps so the entire workpiece can be reached.

The part is flipped and placed on a 5-axis mill to achieve the desired curvatures.

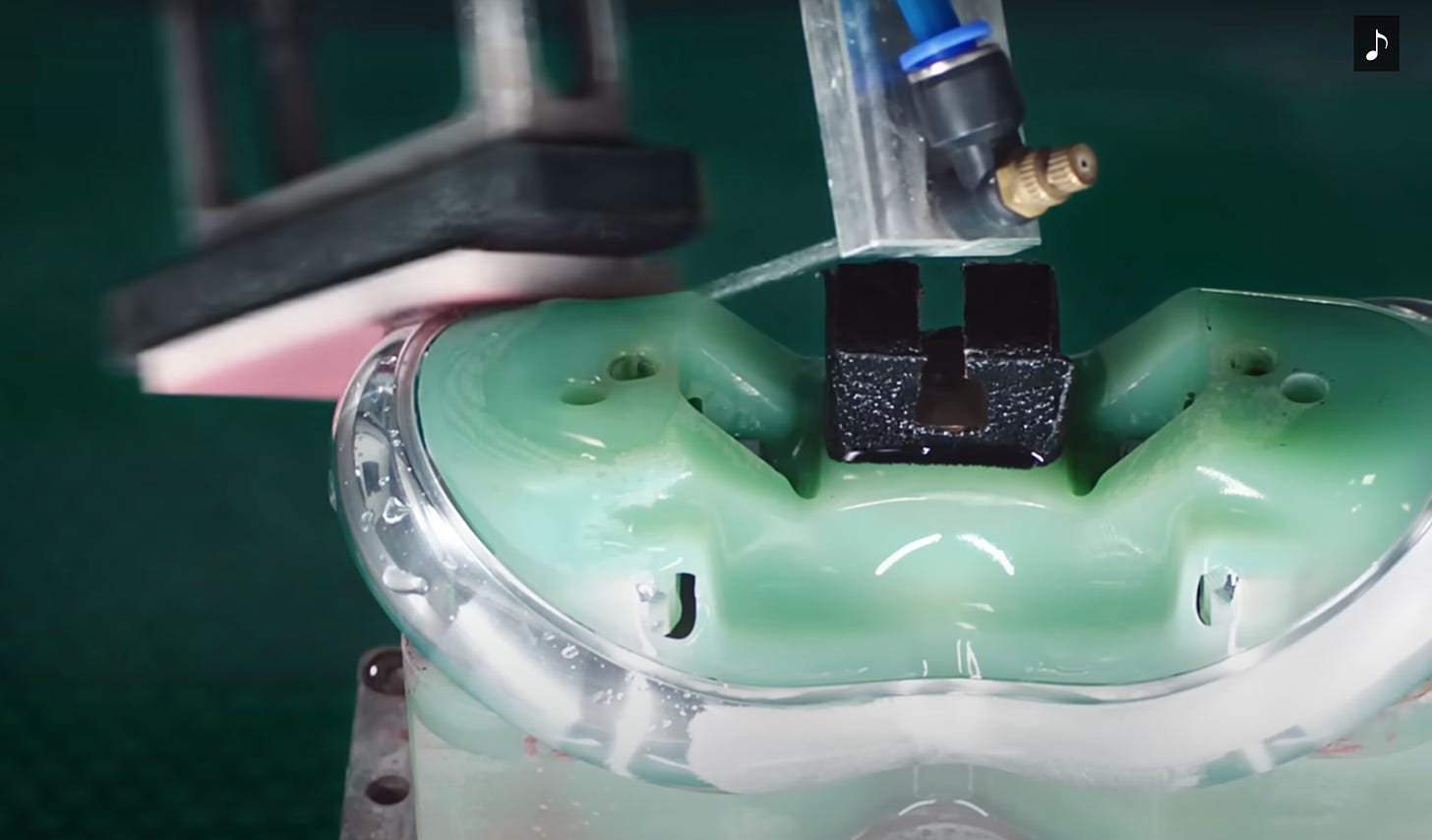

A two step polishing process follows with a vibrating polishing pad and a finishing step using an automated finishing machine.

Another 5-axis mill adds final features to add the slots and holes around the perimeter.

To produce the aluminum frame, think of the sheer number of steps involved for creating a single part! CNC machining is great for prototypes, but not great at scale for consumer devices. Producing a part with similar complexity is feasible through metal casting, but can compromise aesthetic quality, particularly with bare metal finishes where flow lines can be visible. To achieve the level of quality and surface finish, Apple’s solution across all their products has been to buy tens of thousands of CNC machines and even build/buy CNC factories to supply Apple exclusively.

You can watch the full video here which also details other parts such as the glass panel and fabric headband that complete the product.

Question of the Week: Communication Protocols 📡

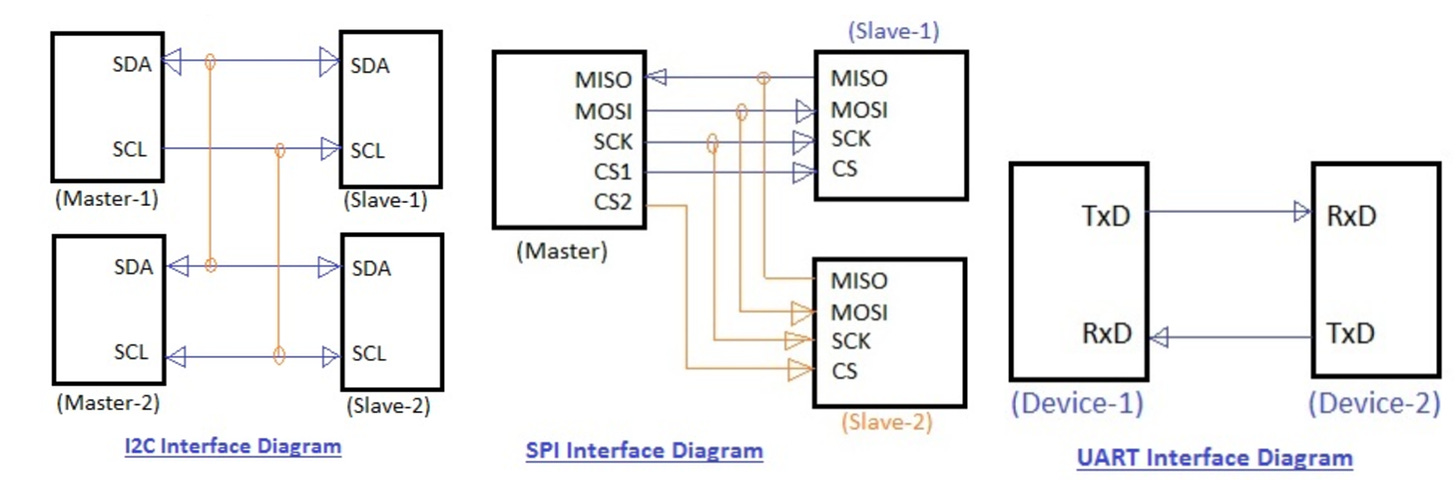

Are you familiar with the three common communication protocols? They’re I2C, SPI, and UART and they dictate how modules communication with each other. Each have their own unique advantages & disadvantages.

I2C:

SDA - Data, SCL - Clock

Bidirectional communication and simple set up

Examples are sensor data transmission and integrated circuit communication

SPI:

MISO - Master Output Slave Input, MOSI - Master Input Slave Output

SCK - Serial Clock, SS - Slave Select

The fastest (10-20 Mbps), full-duplex, but primarily for microcontrollers

Examples are SD card readers and RFID modules

UART:

TxD - Transmit Data, RxD - Receive Data

Simple set up, but the slowest (<=1 Mbps)

Examples are GPS receivers and bluetooth module

See the full discussion here - community support in solving these interview questions is always welcomed!

Interested in more? Check out our resources below.

Great writeup and analysis!