Burn Capital, Build Cathedrals

The Analog #163

Two quick notes to start the year. We’re hosting an online workshop (1/14) on a novel molding process for electronics hardware design, focused on thermal management, EMI shielding, and scalable manufacturing. And we’re hosting our first happy hour of the year in San Francisco on 2/12!

Onshape is offering hardware startups and entrepreneurs free access to Onshape Professional or Onshape Government (compliant with ITAR/EAR). Apply for the program to get started today.

Interesting Links

As power, cooling, and land become binding constraints for terrestrial data center buildouts, some companies are exploring whether compute belongs in orbit instead. The Economics of Orbital vs. Terrestrial Data Centers strips the question down to first principles and reduce it to a single metric, cost per watt of usable compute, where the numbers work out to roughly $50+/W for orbital solar compute vs. ~$15–$16/W on the ground in a baseline model. The governing constraint for orbital datacenters is thermodynamics: with no convection, all waste heat must be rejected by radiation, making radiator area and temperature the binding limit. The original post walks through this rigorously and any short summary would miss the point, but the author also makes a broader case: even if orbital compute looks like a mediocre trade on near-term unit economics, the second-order effects of building power generation and operations infrastructure in space are large enough to justify it as a genuine moonshot worth attempting. A plea for modern-day Medici-style patronage:

“I’ll go one step further and say the quiet part out loud: we should be actively goading more billionaires into spending on irrational, high-variance projects that might actually advance civilization. … If you’ve built an empire, the best possible use of it is to burn its capital like a torch and light up a corner of the future. Fund the ugly middle. Pay for the iteration loops. Build the cathedrals. This is how we advance civilization.”

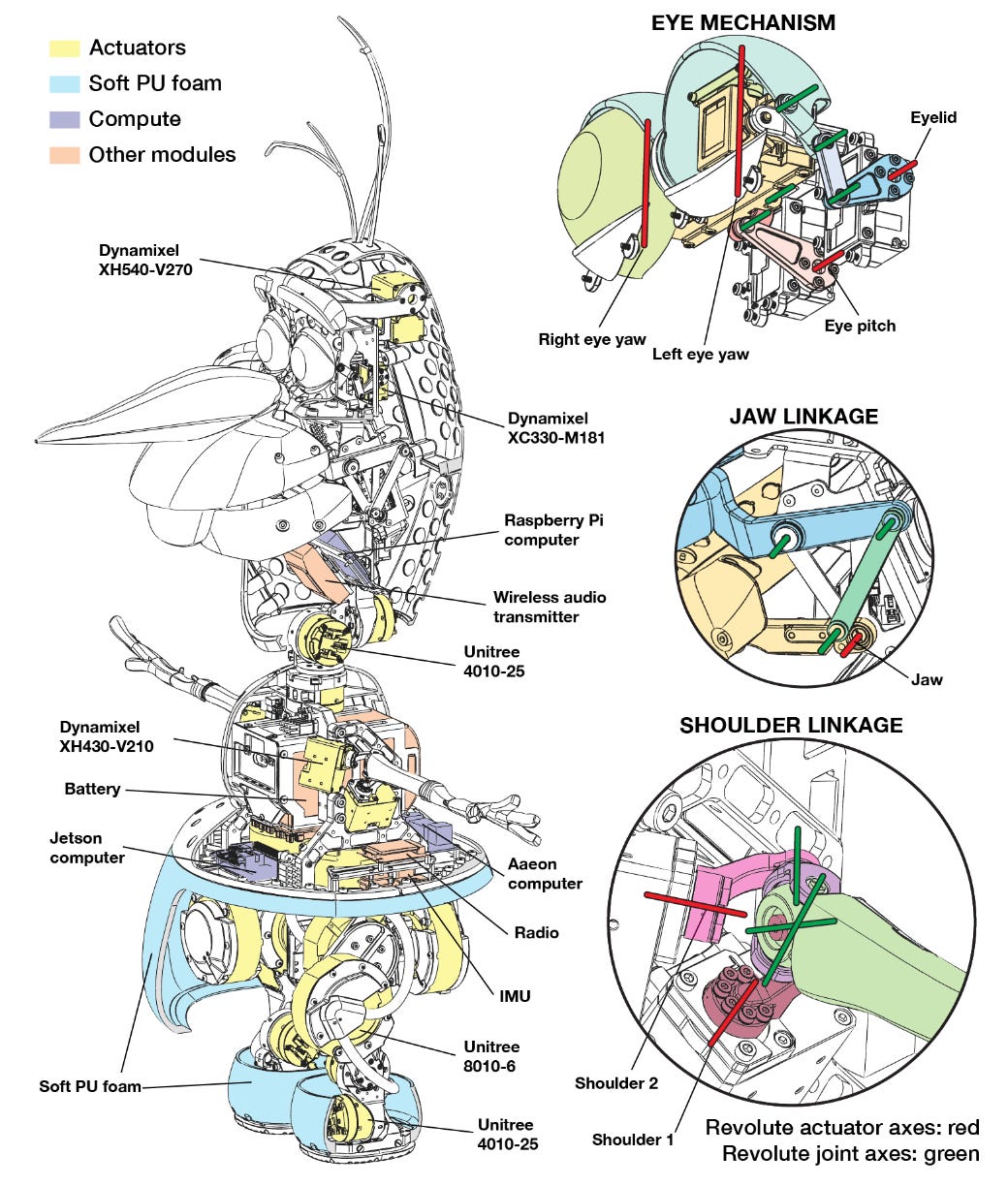

Another great paper from Disney Research on how animated character motion forces novel mechanism design and control in physical robots like Olaf. To create the illusion of Olaf’s feet moving along his body, the system hides two asymmetric legs under a foam skirt, packing a 25-DoF system (6 per leg, 2 per shoulder, 3 in the neck, plus joints in the jaw, eyebrow, and eyes) into a spherical “snowman” envelope. On the control side, they use reinforcement learning as a behavior-shaping tool, training policies that (1) track animated motion while explicitly penalizing foot impact to produce quieter, softer steps and (2) include actuator temperature in the reinforcement learning loop so the policy learns to ease off high-torque motions as components heat up. Full paper here.

A visual walkthrough of industrial-scale SLA 3D printing from our old friends at POP Manufacturing, showing what actually happens inside systems like their new ProJet SLA printer. Unlike fused deposition modeling (FDM)—the more conventional “plastic-filament” 3D printing most people think of—stereolithography (SLA) cures liquid resin with a scanning laser in a neutrally buoyant vat, creating parts that are near-isotropic and highly dimensionally accurate. It’s great for parts where geometry and surface finish matter, and a bad choice when structure, heat, or exposure to UV matter.

A bit of pressure from the current administration paired with renewed investment in U.S. education, is starting to show up in tangible ways. Apple launched the Apple Manufacturing Academy with Michigan State University last year, and is now offering online courses and hands-on consulting for small and mid-sized manufacturers (application required). Topics include a wide range of topics in advanced manufacturing like automation, predictive maintenance, quality control optimization, and machine learning with vision. It’s part of a broader $600B investment plan that also includes a new Texas factory, more direct investment into U.S. manufacturing capacity, and expanded U.S. based work on AI and silicon engineering. (If anyone gets access to the course material, we’d love to take a look!)

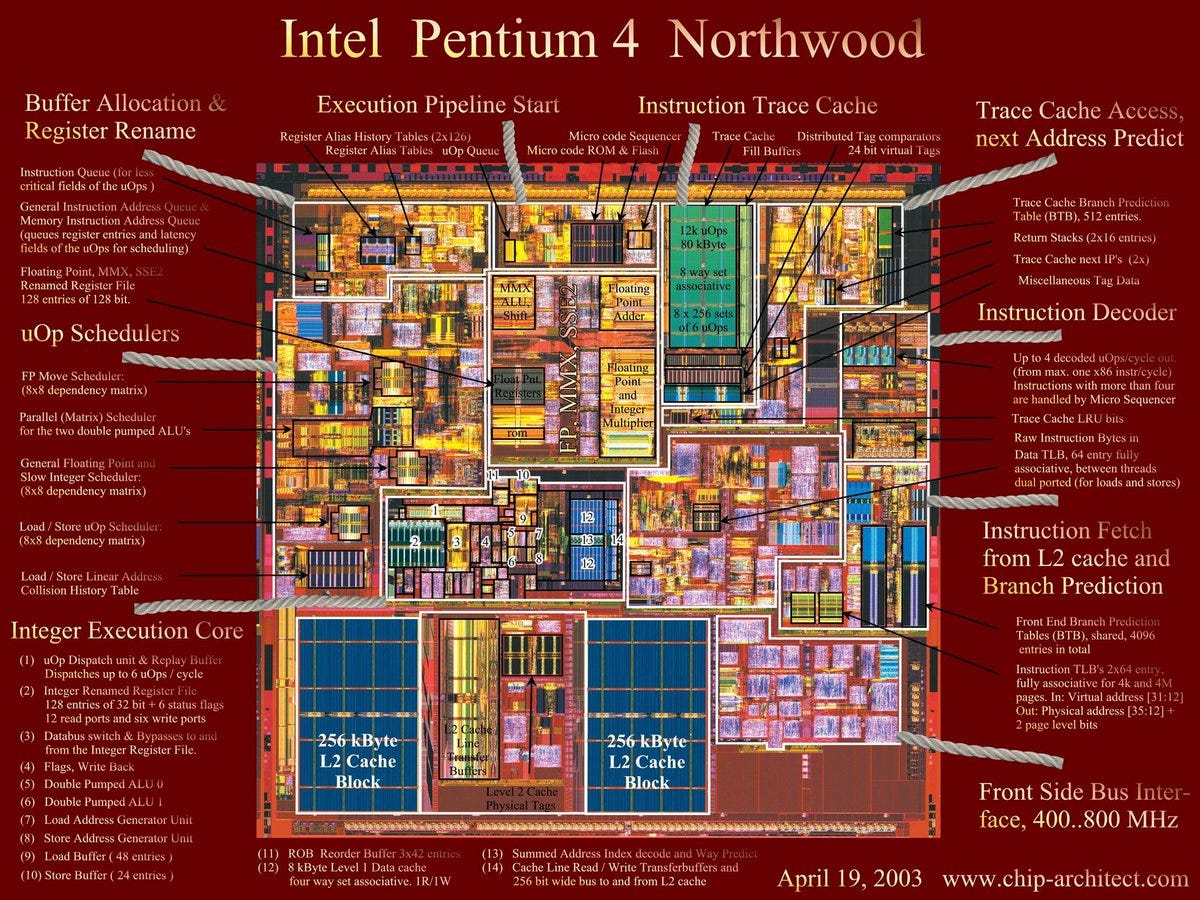

This Northwood die shot captures the peak of the superscalar era, when aggressive clock scaling remained the primary path to performance gains before power walls forced the shift to multi-core parallelism. From external coprocessors in the 1970s and 1980s, like Motorola’s 68851 paged MMU paired with the 68020, memory management evolved into fully integrated, distributed logic by the early 2000s, with scattered TLBs, page walkers in load/store units, and tag checks across caches to minimize latency in deep-pipeline designs such as Intel’s 130nm Northwood Pentium 4.

A couple fun links to round out the week:

One of the best examples of organic marketing we’ve seen recently: SendCutSend was able to machine a pathologically designed CNC part dreamt up by em0sh, mainly to probe the practical limits of their new machining capabilities.

An updated version of buildlist.xyz released over the holidays. Solid directory to browse interesting startups and roles.

Startup News

A recap of a busy holiday stretch for the AI chip industry:

Nvidia signed a $20B non-exclusive licensing deal with Groq, underscoring that inference, not training, is the next contested layer of the AI stack. As part of the deal, Nvidia gains access to Groq’s specialized inference architecture while neutralizing a credible GPU alternative. It’s an implicit admission that GPU generality is no longer optimal for large-scale inference workloads.

Intel is reportedly nearing a ~$1.6B acquisition of SambaNova Systems, a custom AI-chip startup building dedicated accelerators for training and inference workloads. The price would mark a sharp reset from SambaNova’s $5B valuation in 2021, effectively giving Intel a ready-made AI platform at a discount.

Mill signed a commercial deployment deal with Whole Foods via Amazon to roll out industrial versions of its food-waste bins across stores starting in 2027. The company was founded by Nest co-founder Matt Rogers and applies a similar consumer-hardware + data feedback playbook from household thermostats to food-waste handling. The commercial units are designed for continuous, back-of-house use, grinding and dehydrating produce waste on-site to reduce hauling and landfill fees while logging discard data to inform upstream inventory decisions. The company has raised a total of $250 million to date.

Array Labs raised $20M in a Series A round to fund deployment of its space-based radar satellites. The company is building high-power, low-cost radar satellites that operate as clustered constellations to generate 3D radar imagery from multi-angle passes. A four-satellite commercial launch is planned for later this year, with a 16-satellite constellation targeted for 2027. Catapult Ventures led the round,

Open Jobs

More jobs added weekly on our job board. If you’re hiring, promote your open role here.

Early Career:

Medra is looking for a Mechanical Engineer in San Francisco, CA

Boston Dynamics is looking for a Mechanical Engineer in Waltham, MA

Mid-Level:

K2 Space is looking for a Power Electronics Engineer in Los Angeles, CA

Senior to Staff:

OpenAI is looking for an Electrical Engineer (End Effectors) & Firmware Engineer, ASIC Drivers in San Francisco, CA

Neuralink is looking for an Engineering Lab Manager in Austin, TX

Internships:

Varda Space Industries is looking for a Mechanisms/Payload Intern (Spring 2026) in El Segundo, CA

Tools From Our Sponsors

Ops & Collaboration

Boltline – End-to-end engineering platform to design, build, test, and scale hardware fast.

Dirac – Work instructions, automated. Context-aware production planning starts here.

Doss – Adaptive ERP for orders, inventory, and production.

AllSpice – Git-style revision control for hardware designs.

Design & Simulation

Quilter – Fully automates PCB layout with physics-driven AI.

nTop – Computational design to accelerate product development.

Onshape – Cloud CAD with real-time collaboration and version control.

Manufacturing

Loombotic – Instant-quote custom wire harnesses. Upload drawings or design online, fast turnaround.

Express Manufacturing, Inc. – Southern California’s largest EMS provider with 40+ years of end-to-end electronics manufacturing expertise.

Summit Interconnect – Quick-turn complex rigid, flex, and rigid-flex PCBs.

Fictiv – On-demand custom manufacturing from prototype to production.

Access Every Link We’ve Ever Shared 🎞️

Refer three friends to Hardware FYI and unlock our full archive.

Missed an issue? Hunting for that one link? Every tool, guide, and article we’ve ever shared is in here.

P.S. If you find something interesting—an article, tool, funding round, project, really anything—send it our way.

P.P.S. 17,750+ engineers, founders, and operators read this newsletter. If you want to reach them, get in touch.

This is excellant work pulling together the orbital compute economics. The radiator thermodynamics constraint is what most people miss when they get excited about space datacenters, but I actually think the Medici-style patronage framing might be the strongest argument here. We've gotten so used to optimizing every dollar for immediate ROI that we forgot how most big infrastructure leaps actually happened. Actuators and power systems for orbital hardware seem like theyre in that awkward middle phase where unit costs look bad but learning curves havent kicked in yet.