👋 Happy Saturday! This weekend’s highlights include a breakdown of 3D geometry representations and their implications for manufacturing, lecture notes on advanced packaging in semiconductor design, and a deep dive into the capacitor plague that took down a generation of motherboards.

Interesting Chart: Comparing 3D CAD Geometry Formats

Three different ways to represent 3D geometry:

Boundary representation (B-rep): Describes a solid by explicitly defining its surfaces, using faces, edges, and vertices connected together.

Implicit representation: Uses mathematical equations (i.e. f(x, y, z) = 0) to implicitly define surfaces, without explicitly specifying their boundaries.

Tools like nTop use the implicit approach to generate complex geometries that are difficult to model in traditional CAD.

Polygonal surface mesh: Approximates an object's shape by connecting many small polygons (usually triangles or quads) at their edges and vertices.

This is the basis for formats like STL used in 3D printing.

Nick McCleary at Zoo summarizes the practical implications:

At the risk of both repeating myself and sounding combative, an STL file is not really CAD: it can't be driven parametrically, and it can't be used to produce manufacturing drawings. For your product to have any prospect of being useful to real engineers who engage with real manufacturing techniques, where engineers are actually providing real GD&T and real drawings, your system must be capable of generating a B-rep format one way or another.

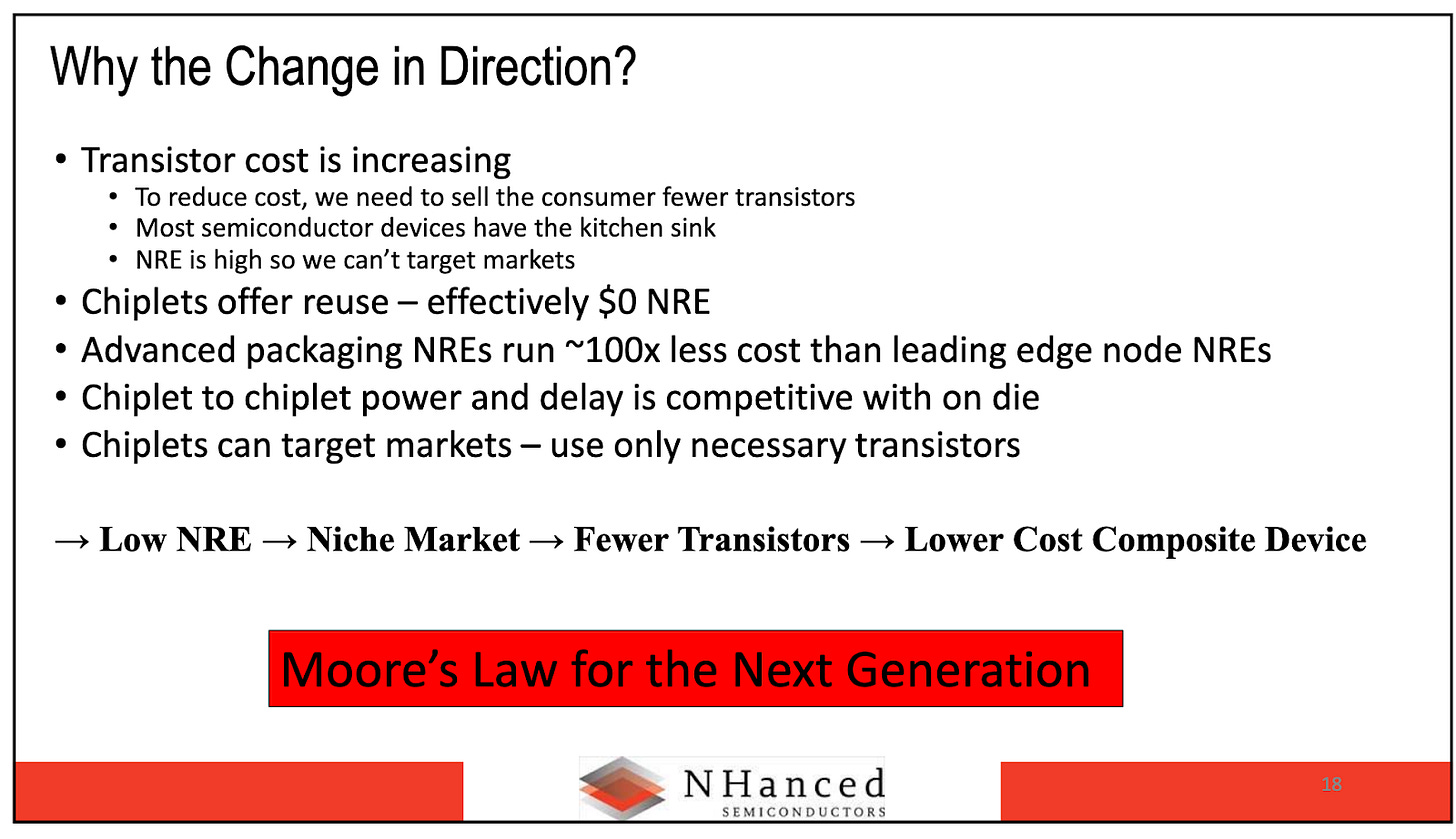

Interesting Lecture Notes: Packaging as the New Performance Lever

For decades, chip performance gains came from shrinking transistors, but that playbook is running out with the slow death of Moore’s Law. Here’s a slide that shows how the focus is shifting from the front end to advanced packaging.

Advanced packaging integrates multiple dies that are often built on different process nodes into a single package. Techniques like 2.5D stacking, fan-out wafer-level packaging, and 3D integration are now standard in high-performance compute applications like datacenter GPUs, AI inference chips, and smartphone SoCs. Instead of one large chip, you get a tightly coupled system of smaller chips, optimized for performance, power, and cost that focus on integrating multiple semiconductor chips or dies into a single package.

Refer a Friend, Get a T-Shirt! 👕

If you like the newsletter, chances are you know a few others who would too. Refer five of them, and we’ll send you a t-shirt. No strings attached. Just a simple thank you.

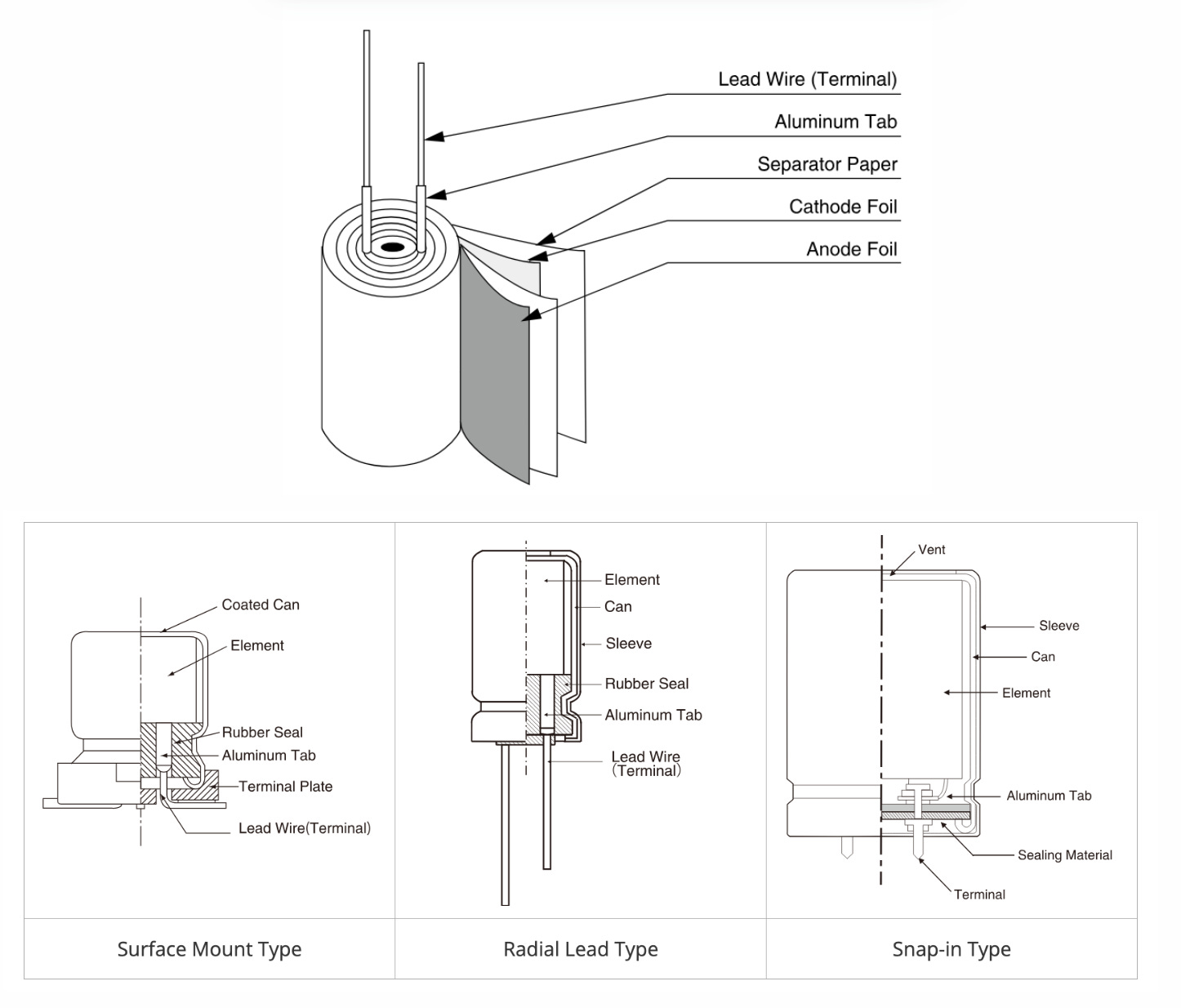

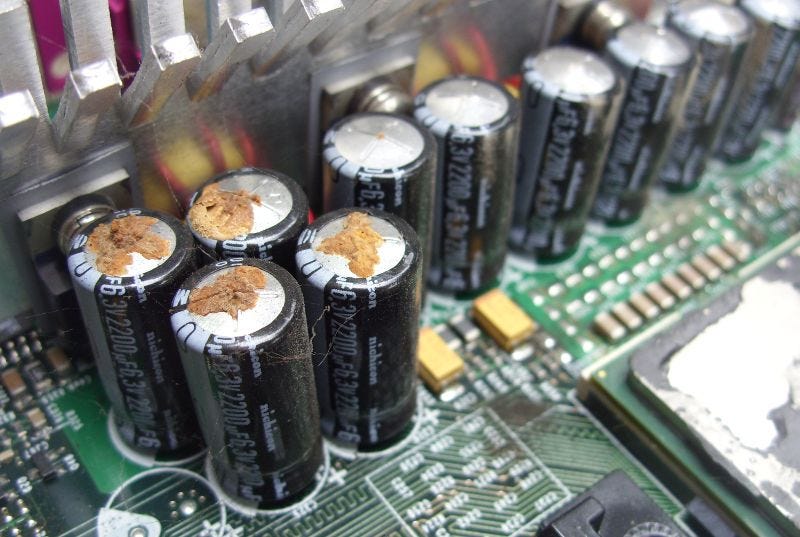

Interesting Video: The Capacitor Plague

In the early 2000s, PC motherboards and consumer electronics began failing due to bulging or exploding capacitors. This event became known as the Capacitor Plague, a widespread failure of specifically non-solid aluminum electrolytic capacitors, also known as aluminum e-caps.

The video above from Asionometry does a great job covering the history of the capacitor plague and potential root causes. The recent Deel-Rippling scandal brought corporate espionage back into the spotlight (separately—worth reading on its own!), but this was far from the first case of bad actors. In 2001, a Japanese scientist allegedly stole a water-based electrolyte formula from Rubycon and shared an incomplete version with Taiwanese manufacturers, where missing additives led to hydrogen gas buildup resulting in unstable capacitors prone to leaking or bursting. The result was widespread failures with OEMs like HP, Apple, and Dell even paying $300M to cover costs with failed capacitors.

Fun fact: You can still find a list of bad capacitor manufacturers on the Bad Caps Forum.

Manufacturing & Startup News

More leftovers from our weekly research in hardware and manufacturing news:

Dexterity raised $95M USD to advance development of their dual-armed system for logistics automation.

Rocket Lab USA announced a non-binding agreement to acquire a controlling stake in Mynaric, a laser communications provider, for approximately $75M USD with a further $75M in earnout options. Mynaric raised $300M total in funding.

Zeitview secured $60M USD to enhance its AI-powered inspection capabilities for global critical infrastructure.

Whiskey Bravo Group delivered its first next-generation missile boats to the U.S. Marine Corps.

Fleet Space acquired HeiSei, a startup specializing in hard rock seismic technology, to expand its end-to-end mineral exploration services.

Thanks for reading to the end - if you’ve enjoyed the mechanics of these insights, consider sharing this issue with a fellow enthusiast!

Would agree, STLs aren’t really CAD. Sort of like how gerbers aren’t the same thing as native EDA files.

I somehow made it through that era largely unscathed. I remember a lot of time looking over mobos for bulging capacitors though. Thanks for taking me back.