We’re hosting our first Engineers and Founders Dinner in Portland on April 10th! Applications are open – hardware engineers, leaders, founders, and investors are all welcome!

Onshape is offering hardware startups and entrepreneurs free access to Onshape Professional—complete with CAD, rendering, simulation, PDM, and more. Apply for the program to get started today.

Interesting Links 🏭

With the launch of BotQ, Figure’s manufacturing facility for its production-intent humanoid robot, a question comes to mind: why commit so much to tooling and NRE when the design is still evolving? Figure’s announcement video breaks down how they produce the face plate in a style reminiscent of Apple’s manufacturing videos. From the video, it looks like they’ve put over $1M into tooling and non-recurring engineering (NRE) costs for a single part—custom injection mold tooling, automated fixturing for material handling, and multiple bespoke secondary steps with robotic arms from Yaskawa, ABB, and Universal Robots. At volumes as low as 12,000 robots per year, automation is usually a mistake. Early production runs, field tests, and scaling inevitably expose design flaws, and if you've automated too soon, you're stuck retooling expensive equipment instead of making quick manual adjustments. These threads add more color about the risk of automation so early:

‘There’s a complex path dependency trade that happens when you start tooling expensive parts in proto; it’s great to have real parts for scaled pilots, but dangerous to give the current design inertia vs. minimizing reaction time to field learning.’ [1]

“Your startup is not Apple when the Apple juggernaut was firing on all cylinders. You do not have the capital runway to call Yaskawa to beat them up on robot pricing, or the paint booth producers to make your little helmet sprayer and sell it to you at 75% the normal market rate because you are Apple, and you have the best procurement people in the world who beat the [hell] out of vendors at the negotiating table.” [2]

A few weeks ago in issue #118, we mentioned that the FCC database holds internal design docs for almost any electronic device. That got us curious, so over the past month we pulled teardown documentation for every product we could think of and built a database. Here’s the link. Happy sleuthing!

P.S. if you want to contribute, just drop the product name or FCC ID into this form and we’ll add it to the airtable.

If you’ve ever spent time waiting to save a file, there’s a good chance the storage medium in your computer contributed to the delay. Since the 1950s, storage media—tape drives, hard drives, and SSDs—have all evolved to become cheaper and more efficient. Tape drives, primarily used for long-term storage applications (yes, AWS still uses them) have an extremely slow read/write cycle for random operations—up to seven times longer than sequential ones. Hard drives improve performance with a mechanism called a platter, which spins at high speed and stores data in circular segments rather than a straight line. This enables speeds thousands of times faster than tape, though mechanical action is still required to retrieve data. Enter solid-state drives (SSDs), or flash storage, the current state-of-the-art for non-volatile memory. SSDs can read and write data using electrical signals alone, achieving random read operations in as little as 16 microseconds. However, there are caveats: SSDs store data in minimum “chunks,” and when overwriting data, it must first be explicitly erased. This leads to the well-known issue of “garbage collection,” which the blog explores at a high level.

Scientists have proposed turning old coal mines into gravity batteries, where excess energy is used to winch up heavy weights and energy is conversely generated when they fall. This method could help store renewable energy long-term, stabilizing the grid and repurposing mine shafts. The US alone has 550k abandoned mine shafts, huge potential if this technology succeeds. The first commercial project in Rudong, China, stores 100 MWh, and global estimates suggest up to 70 TWh storage capacity, an unexpected detail given the scale. This could play a key role in supporting renewable energy transitions, offering a sustainable solution for energy storage.

Flint Engineering's IsoMat achieves heat transfer efficiency 5,000 times that of copper or aluminium using a flat aluminium sheet with internal channels. The manufacturing process and the working fluid of the IsoMat is not disclosed. However, it could improve thermal management in buildings, refrigeration, and electric vehicle batteries, potentially saving up to 30% energy in refrigeration. Commercial deployment is planned, and this could be a valuable heat sink for use in heat pumps and air conditioning units.

A fun project to round out the week: a student knitted a functional breadboard as part of the ITP Stupid Hackathon at NYU. The event’s tagline? Do you have an idea so absurd, so utterly useless, that it needs to exist? Welcome to Stupid Hackathon 2025!

Sponsored: Presented by Sygma

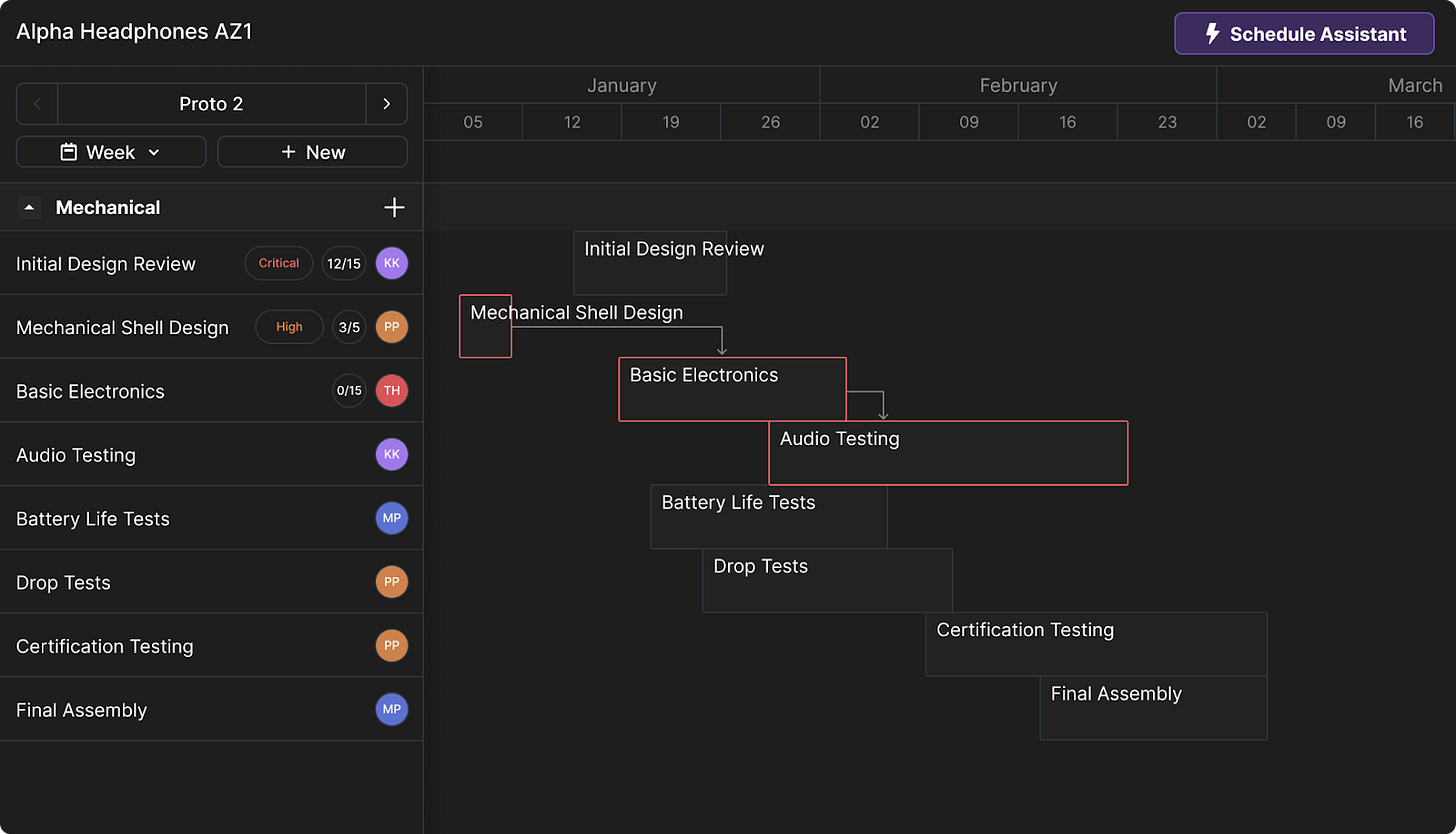

Sygma is excited to launch their new Schedule Assistant—an AI partner designed to simplify scheduling and keep projects moving. The scheduling assistant can:

✅ Find weeks of time savings by automatically analyzing your critical path and highlighting bottlenecks.

✅ Stay on top of deadlines as it pulls key dates from your existing communication channels.

✅ Proactively suggest schedule updates when new information comes in.

No more wasted time and surprises. Just a schedule that works. Check out Sygma’s tool here.

Startup News 🚀

Some new announcements at the executive level:

Another Google veteran moves into hardware—Eric Schmidt, the former CEO of Google, is the new CEO of Relativity Space after taking a controlling interest in the company. Relativity was originally known for its fully 3D-printed rockets, but has shifted to a hybrid manufacturing approach for its Terran R rocket using traditional methods for larger components while still leveraging additive manufacturing for critical parts like their engines.

Lip-Bu Tan has been appointed Intel's new CEO, moving from semiconductor design software at Cadence to now leading one of the world’s largest chipmakers. SemiAnalysis wrote a great read on the state of Intel at the end of 2024—spoiler: it was not looking great.

Terabase Energy, a leader in solar automation, raised a $130M Series C funding round to revolutionize utility-scale solar construction. The capital will accelerate the deployment of their Terafab™ system, a robotics-assisted solution already proven with 40 megawatts installed, targeting hundreds more in the coming years. This investment bolsters their mission to cut costs and timelines for large-scale solar projects, meeting the rising global demand for renewable energy. The round was led by SoftBank Vision Fund 2, with participation from other strategic investors.

Shield AI raised $240M in a Series F-1 funding round boosting its valuation to $5.3B. The funds will be used to scale the Hivemind Enterprise platform, an AI-powered autonomy system driving applications from drones to robotics across industries. This milestone positions them as a top player in autonomous technology, nearly doubling their prior valuation and reflects a surge of interest in defense solutions. Key investors include L3Harris and Hanwha Asset Management.

Mixergy, raised a $15.5M funding round for smart hot water cylinders. The company is planning to develop a technology licensing model and expand R&D for energy-efficient installs in new builds, social housing retrofits, and commercial properties. The funding round was led by Barclay's Climate Ventures.

Northvolt AB and some subsidiaries filed for bankruptcy in Sweden on March 12, due to rising capital costs, geopolitical instability, and production challenges. Despite doubling cell output and delivering the first million battery cells using 100% fossil-free energy, they couldn't overcome financial hurdles. The process will be managed by trustee Mikael Kubu, with some subsidiaries not filing.

Refer a Friend, Earn Rewards 🎁

Refer just one friend to Hardware FYI, and we’ll send you our complete database of resources—every design guide, article, white paper, and more.

Open Jobs 💼

Early Career:

The Engine is looking for a Resident Mechanical Engineer in Cambridge, CA

Nvidia is looking for an ASIC Design Efficiency Engineer (New Grad) in Santa Clara, CA

Boeing is looking for an Associate Structural & Payload Design Engineer in Titusville, FL

Mid-Level:

Wing is looking for an Electrical Engineer in Palo Alto, CA

Formlabs is looking for a Systems Integration Engineer in Somerville, MA

Carbon Robotics is looking for a Field Robot Engineer (AutoTractor) in Seattle, WA

Senior to Staff:

Engineered Arts is looking for a Humanoid Robotics Operation Engineer in Redwood City, CA

Lumindt is looking for a Systems & Process Engineer in San Francisco, CA

Anduril is looking for a Senior Materials Engineer (Polymers) in Costa Mesa, CA

Internships:

Lumindt is looking for a Data Science Intern in San Francisco, CA

Ambi Robotics is looking for a Mechanical Engineering Intern in Berkeley, CA

Want to share an exciting role at your company? Reach out here.

Meet our Sponsors:

Quilter helps teams save valuable engineering time by fully automating PCB design with physics and AI.

nTop accelerates product development with computational design.

Onshape is a cloud-native CAD platform that enables real-time collaboration, built-in version control, and design management for engineering teams.

Dystr is an AI assisted math and analysis environment designed to accelerate your engineering velocity by 10 - 100x.

Doss is an adaptive ERP — manage orders, inventory, procurement, production and more without changing how you work.

Summit Interconnect is a manufacturer of advanced technology printed circuit boards focused on complex rigid, flex and rigid-flex PCBs.

Cofactr is an automated electronic component procurement and inventory management platform.

AllSpice.io is the Git for hardware collaboration platform, connecting native engineering design tools to provide revision control, automation and more.

Looking to get ahead in your career? We offer interviewing resources for engineers!

For all resources available, check out our home page.

Thanks for reading to the end - if you’ve enjoyed the mechanics of these insights, consider sharing this email with a fellow enthusiast!

The gravity battery is a pretty neat idea. Reminds me of how hydroelectricity ponds (if that is the term) are used for a similar purpose, but with water pumps and turbines.

On the gravity battery front: here is a US startup that is deploying them: renewellenergy.com. I've met one of the founders, and he's a great guy.