Onshape is offering hardware startups and entrepreneurs free access to Onshape Professional—complete with CAD, rendering, simulation, PDM, and more. Apply for the program to get started today.

Interesting Links 🏭

A closer look at how SpaceX actually operates, both at an individual productivity level and in how its structure and engineering philosophy shape design requirements.

At the individual contributor level, the culture is built entirely around speed: move fast, return feedback within hours, and never let work stall while it’s in your court. Engineers are expected to overcommunicate priorities, clear blockers in real time, and drive the cadence with vendors - not the other way around. During the early Starhopper sprint (first prototype of the Starship program), the directive was to ignore cost, efficiency, and repeatability so the team could solely focus on building the first prototype as fast as possible. That clarity led to decisions like using tents instead of buildings and hiring water tower welders to fabricate rocket structures.

At the organizational level, the company operates on a model of distributed ownership vs. a centralized systems engineering model typical of aerospace and defense contractors. The observation: systems teams can act as gatekeepers that can slow down iteration and separate requirements from implementation. SpaceX flips this where every engineer is a Responsible Engineer (RE) who’s accountable for both designing and scoping requirements. ‘Everyone is a systems engineer, or no one is.’ It’s faster to get something wrong quickly 3 times and then right the 4th, than it is to get it perfectly right the first time, and take 20 years to do so. This is the core principle of the iterative/agile approach.

Energy consumption benchmarks for various AI inference tasks, ranging from text to video generation. Hugging Face tested open-source models using Nvidia H100 GPUs in controlled conditions and found a wide variation depending on the task and architecture; for example, image generation models like Stable Diffusion require 1.6 kWh per task, while some models perform the same benchmark at just 0.1 kWh. Other LLM tasks (text generation, summarization, classification) use far less energy and only consume a few watt-hours per task. Data centers running AI servers like this consumed ~4.4% of total U.S. electricity in 2023, and are projected to reach anywhere from 6.7–12% by 2028. Full benchmarking methodology here.

This is an interesting case study on forced obsolescence and getting creative with one-man factories. A solo engineer built a USB-C replacement case for first-gen AirPods using a fleet of SLS printers and a custom PCB that bridges Lightning to USB-C. To print more product colors, he used white nylon 12 instead of the standard gray in most SLS printers, and then batch-dyed parts using an ultrasonic cleaner and off-the-shelf clothing dye. Apparently, if you also search hard enough, dedicated dyeforming systems for 3D printed parts (~$5k) are just sous vide cookers available at wholesale prices on Alibaba for a fraction of the cost.

Before Nest was acquired by Google in 2014 for $3.2B, half of Nest’s revenue came from government programs, where utilities and agencies paid to install smart thermostats to help reduce energy use. A useful reminder that even one of the biggest consumer hardware exits of the last decade depended heavily on incentive-driven adoption tied to state programs and regulatory frameworks.

Some interesting software design principles with a ‘local-first’ priority. The core idea is that software should work offline, sync across devices, and give users full control over their data including privacy, security, and long-term access. Modern cloud apps too often trade away this flexibility, unlike older monoliths that didn’t require a connection to the cloud. Local-first proposes seven principles for keeping core functionality on-device and using the cloud for discovery, backup, and burst compute.

Quilter’s been running a great series of interviews with engineers from across industry. This one features an engineer who spent over six years at Walt Disney Imagineering (including work on the Zootopia project), and is now at a research institute where the work is driven more by open questions than by business strategy. Worth a read for a look at what changes when you're not building for a market!

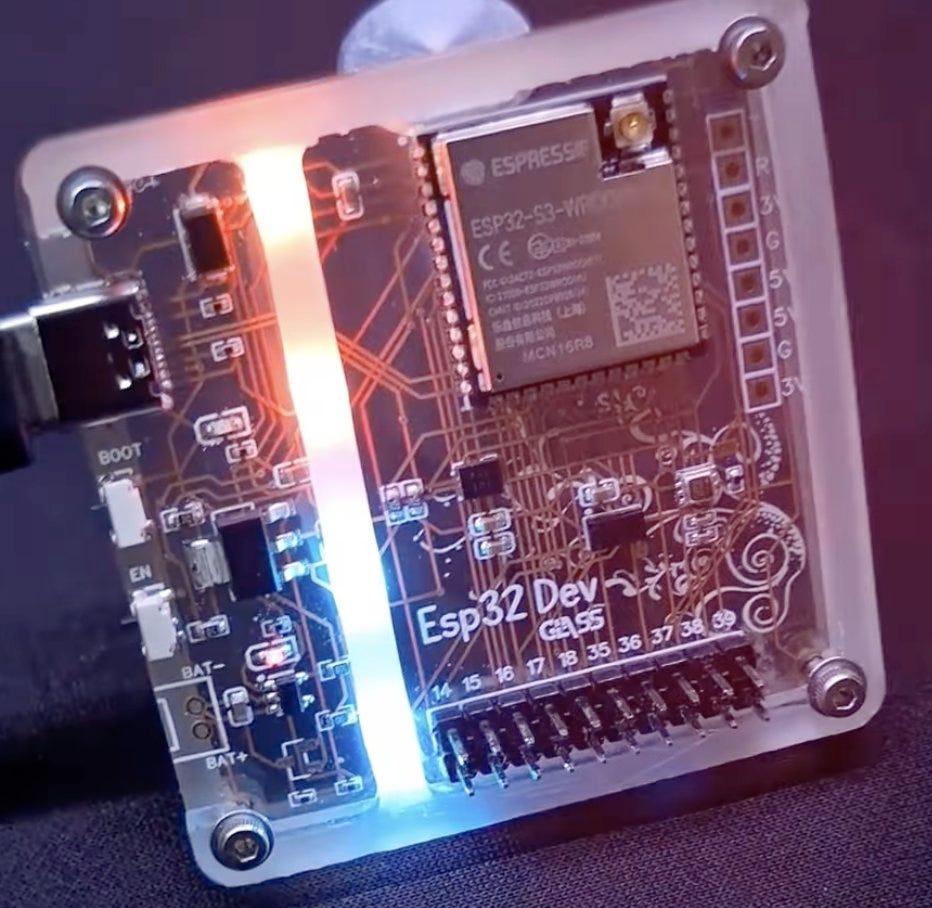

This is a translucent flex PCB made using a standard 2-layer process with outer copper layers and a PET substrate in between.

Sponsored: Presented by Loomia

Loomia’s Smart Skin Dev Kit is built for robotics teams working on dexterous manipulation and humanlike interaction. The kit includes both capacitive and force-sensitive resistor sensors in flexible formats that conform to curved and high-friction surfaces. It’s plug-and-play, tested in the field, and ships later this year. Check it out here.

Startup News 🚀

A tough break in climate and construction tech: Urban Machine, a startup developing robotics to reclaim construction lumber, has paused operations and technology development citing low market demand for reclaimed lumber. While the company still believes reclaimed lumber is key to reducing construction costs and embodied carbon, sales haven’t materialized at the scale their American Canyon facility was built to handle. The company previously raised $14M and is now exploring options to sell or license its technology.

Civ Robotics, a construction robotics startup, raised $7.5M in Series A funding to advance its autonomous surveying technology. Their flagship product, CivDots, uses unmanned ground vehicles to mark thousands of coordinates daily for infrastructure projects like solar farms and roadways. The funding will drive global expansion and further development of the core robotics platform. The round was led by AlleyCorp.

Nissan is in talks to let Foxconn build EVs at its Oppama plant, potentially saving the site from closure amid broader restructuring plans. The move would preserve jobs for existing factory workers and mark another step in Foxconn’s expansion into contract EV manufacturing. Foxconn has been developing EVs under the Foxtron brand since 2020 and recently signed an MOU with Mitsubishi to supply EVs for Australia and New Zealand.

Emerald AI, a startup tackling data center power demands, emerged from stealth with $24.5M in seed funding. Their software manages energy consumption, prioritizing critical tasks to reduce grid strain. A Phoenix pilot with Oracle and Salt River Project cut AI power demand by 25% during peak times. The round was led by Radical Ventures and backed by NVIDIA and other prominent investors.

Blue Origin's New Glenn rocket will target Mars on its second mission, carrying a NASA payload to study the Red Planet. The rocket’s debut will be a certification flight for the U.S. Space Force, carrying a payload to demonstrate the rocket's capabilities.

Open Jobs 💼

More jobs added weekly on our job board. If you're hiring, promote your open role here.

Early Career:

Peloton is looking for a Mechanical Test Engineer in Woodinville, WA

Eyebot is looking for an Electrical Engineer in Boston, MA

Mid-Level:

Shift Robotics is looking for an Embedded Software Engineer & Mechanical Engineer in Austin, TX

Wing is looking for a Reliability Engineer in Palo Alto, CA

Snap is looking for a Hardware TPM in Los Angeles, CA

Senior to Staff:

1X is looking for a Senior Hardware Test Engineer in Palo Alto, CA

Sesame is looking for an Electrical Engineer in San Francisco, CA

Internships:

Figure is looking for an Electrical Engineering Intern (Fall) in Sunnyvale, CA

Tools From Our Sponsors

Design & Simulation

Quilter – Fully automates PCB layout with physics-driven AI.

nTop – Computational design to accelerate product development.

Onshape – Cloud CAD with real-time collaboration and version control.

Dystr – AI math environment that slashes analysis time 10–100×.

Ops & Collaboration

Doss – Adaptive ERP for orders, inventory, and production.

AllSpice – Git-style revision control for hardware designs.

Manufacturing

Dirac – Work instructions, automated. Context-aware production planning starts here.

Summit Interconnect – Quick-turn complex rigid, flex, and rigid-flex PCBs.

Fictiv – On-demand custom manufacturing from prototype to production.

Formlabs Fuse – Office-ready SLS printer for in-house nylon production with industrial part quality.

If you're prepping for interviews, we've put together practical resources for engineers. For all resources available, check our home page.

Access Every Link We’ve Ever Shared 🎞️

Refer three friends to Hardware FYI and unlock our full archive.

Missed an issue? Hunting for that one link? Every tool, guide, and article we’ve ever shared is in here.