👋 Happy Saturday! This week’s highlights include a step-by-step playbook for launching medical device startups, a tour inside K-Scale Labs’ humanoid robot hacker house, and a reference map of the semiconductor value chain tracking lithography tools and equipment vendors.

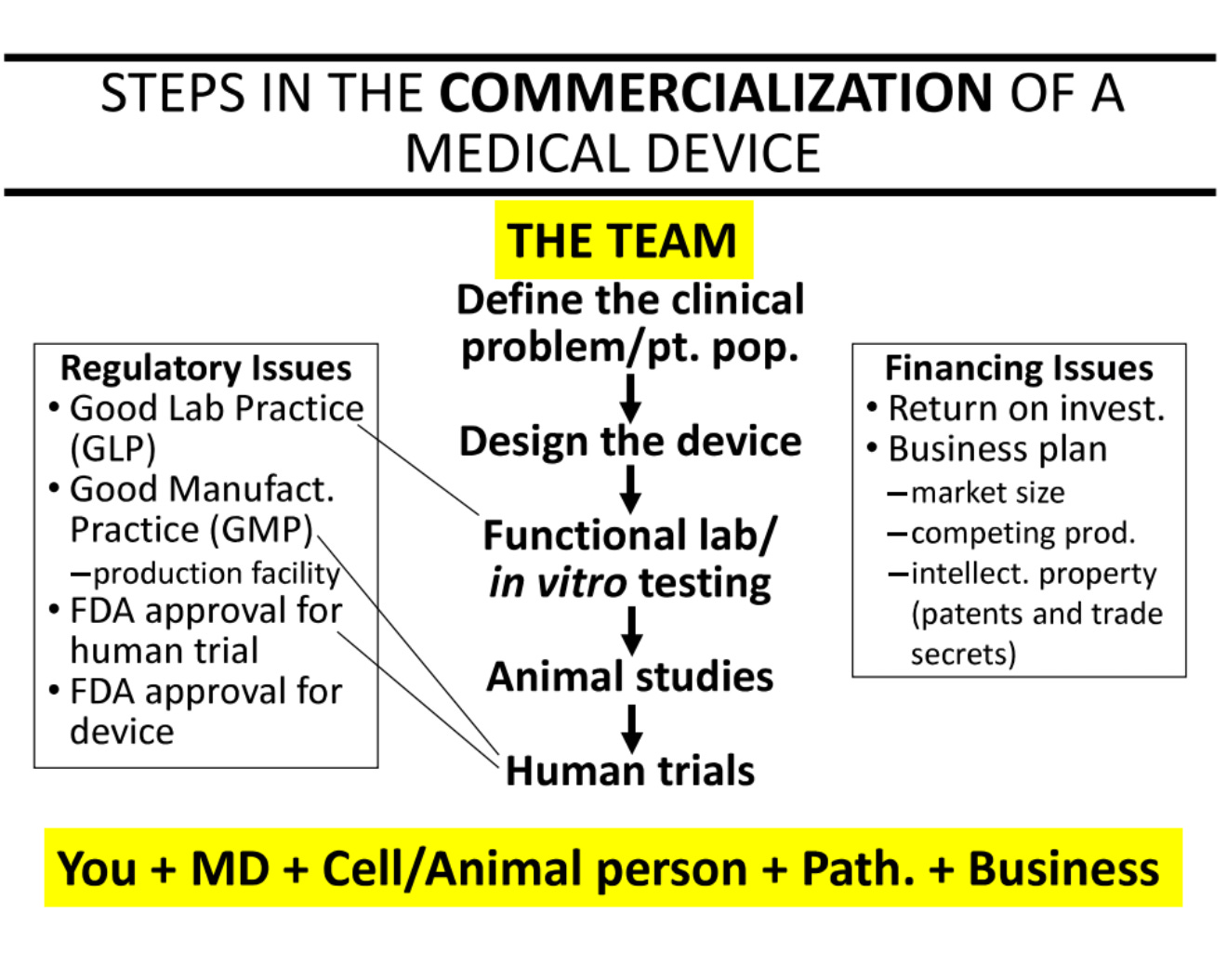

Interesting Lecture Notes: Steps to Building a Medical Device Startup

Spinning out a medical device startup isn’t like launching a typical company, or even most hardware startups. This MIT lecture walks through the medtech commercialization playbook, where patents come before proof and licensing is often more viable than building end-to-end.

Some key dynamics to note:

Patents are frequently filed before technical validation. This front-loads IP protection to account for long regulatory timelines, even if the device concept isn’t fully proven.

In many cases, licensing is a common commercialization path. Academic spinouts often transfer IP to established firms (e.g. Medtronic) with in-house regulatory, testing, and distribution channels.

For more upside and control, going direct-to-market means navigating multi-year FDA approvals and clinical validation long before meaningful revenue.

Interesting Video: Touring K-Scale Labs’ Hacker House

An inside look at K-Scale Labs, a small startup working on a modular, open-source humanoid robot designed to be built at scale for around $11K. The whole team lives and works out of a rented mansion in California, with desks in the dining room and robot testing in the backyard.

Highly recommend watching - lots of unfiltered commentary on the humanoid robot hype cycle, early-stage hardware realities, and their strategic bet on open-sourcing the design to bootstrap an ecosystem rather than defend a moat.

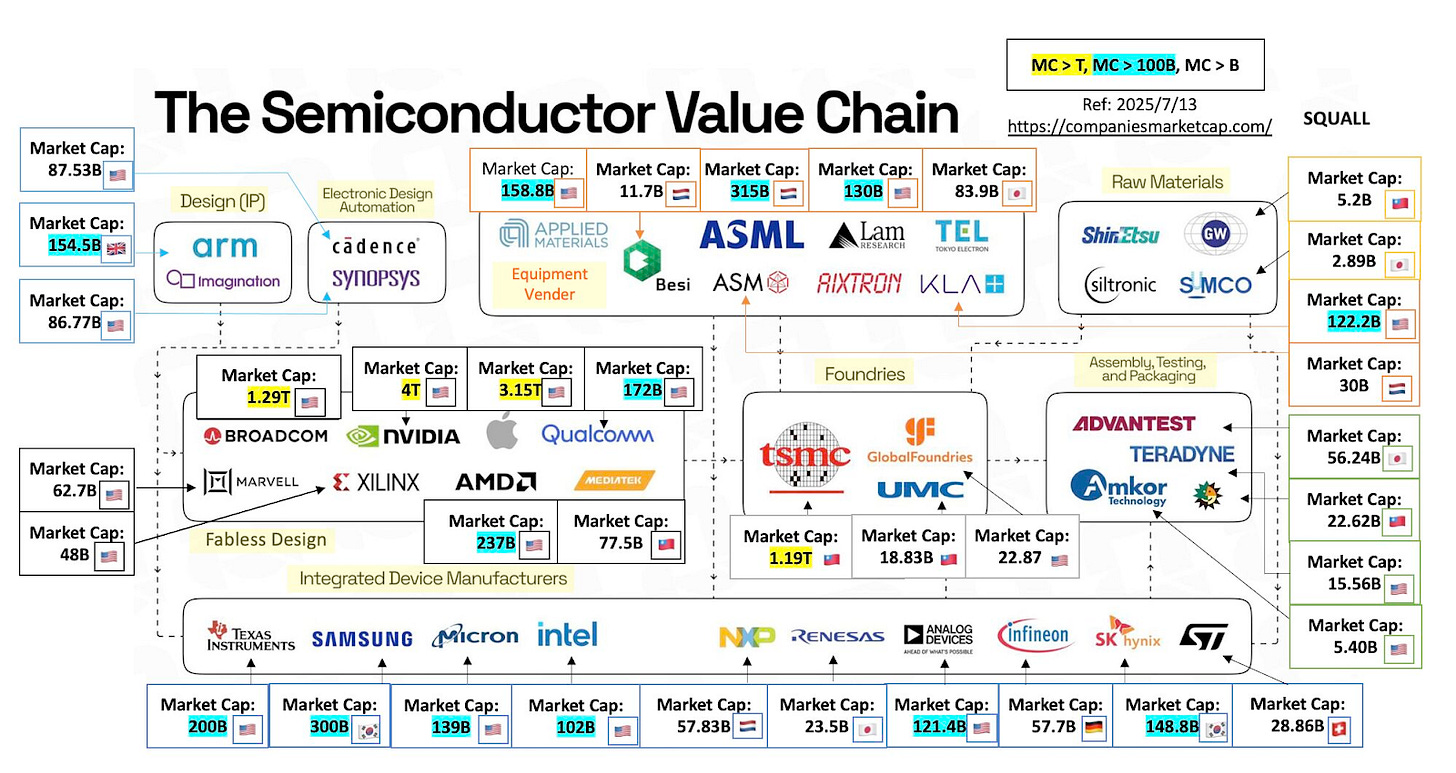

Interesting Chart: The Semiconductor Value Chain

A reference map of the semiconductor value chain from raw materials to packaged ICs.

Design is where revenue first appears: fabless firms (like AMD) and integrated device manufacturers (like TI or Intel) develop chips and sell them to customers. Fabless firms outsource fabrication to foundries (TSMC, GlobalFoundries), while IDMs integrate the whole flow, operating their own fabs and process nodes.

Tooling is upstream. Foundries depend on equipment vendors like ASML for lithography (process of projecting nanoscale patterns onto silicon using extreme ultraviolet light), and a web of vendors for deposition, etching, and metrology gear. Raw material suppliers provide high-purity silicon, gases, and wafers.

EDA vendors like Synopsys and Cadence enable the design process with software, where ARM and others license architecture-level IP are used across many chip families. After fabrication, everything moves downstream to assembly, test, and packaging.

The full chain is highly fragmented and expensive to scale, which is why few companies do everything and those that do operate more like scaled infrastructure than startups.

(If you want a visual sense for how some of this looks in practice, we covered the use of lithography in PCB fabrication here. Same basic idea, but on a much simpler scale than chip fabrication.)

Presented by First Resonance: Rethinking Factory Intelligence

Traditional automation struggles to keep pace with modern production demands. This new eBook, The Agentic Shift: Building Intelligence Into the Fabric of Industry, explores how forward-thinking manufacturers are moving beyond dashboards and static scripts to agentic systems that sense, decide, and adapt in real time. The free guide offers a practical framework for building smarter, more resilient operations powered by AI agents.

Download your copy and start shaping the future of manufacturing.

Manufacturing & Startup News

More leftovers from our weekly research:

Armada raised $131M in strategic funding for megawatt-scale modular AI data centers with liquid cooling for remote environments.

MIT spinout Cambridge Terahertz raised a $12M seed round for terahertz sensors enabling 3D box scanning in supply chains.

Relativity Networks raised $6M for hollow-core fiber enabling ultra-low-latency networking in AI data centers.

Philadelphia-based Asylon raised $24M in Series B funding for autonomous security drones and robotics designed for perimeter and rapid response security.

Delaware-based TRIC Robotics raised a $5.5M seed round for UV-light weeding robots in agriculture.

Access Every Link We’ve Ever Shared 🎞️

Refer three friends to Hardware FYI and unlock our full archive.

Missed an issue? Hunting for that one link? Every tool, guide, and article we’ve ever shared is in here.

Thanks for reading to the end - if you’ve enjoyed the mechanics of these insights, consider sharing this issue with a fellow enthusiast!