👋 Happy Saturday! This week's highlights include lecture notes on welding and joining techniques for mechanical assemblies, a breakdown of Tesla's Optimus robot costs, and insights into developing a battery-powered induction stovetop.

Interesting Lecture Notes: Joining Techniques for Mechanical Assembly

Most parts aren’t useful on their own. You machine them, cast them, or print them—and then you bolt, weld, glue, or press them into assemblies that do something. This week’s lecture from a 2004 MIT course on mechanical joining and welding techniques covers how those connections actually work.

Fun fact: razor cartridges are typically assembled using pulsed laser welding! Short-duration pulses (on the order of milliseconds) at power levels up to 100 kW are used for spot welds in thin stainless steel components, like for compact assemblies such as multi-blade cartridges.

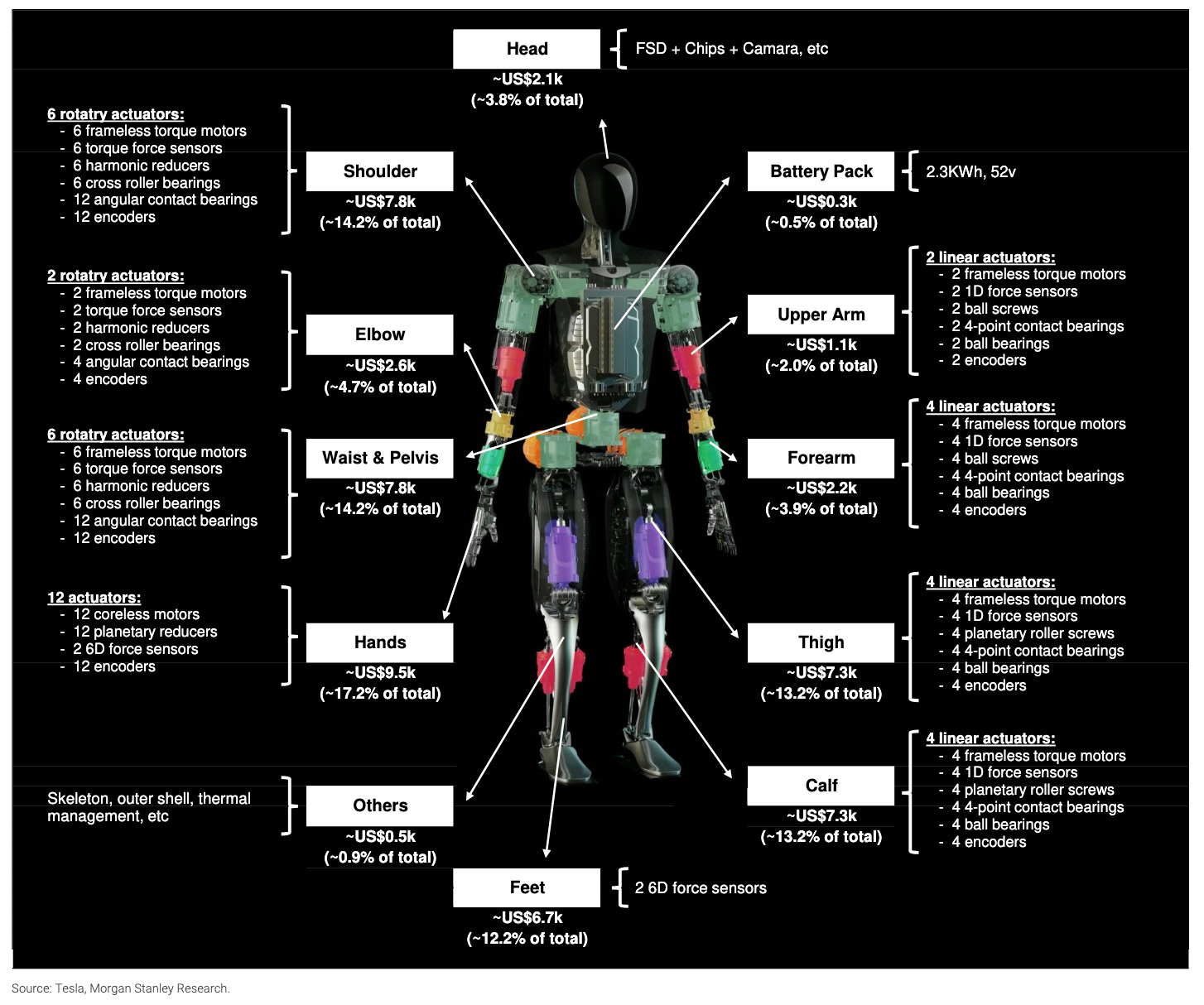

Interesting Chart: BOM Breakdown for Tesla’s Optimus Robot

From a recent Morgan Stanley report mapping the humanoid robotics value chain: a rough estimate of the bill of materials (BOM) cost for Tesla’s Gen 2 Optimus, along with a global map of integrators including suppliers tied to each subsystem.

A few quick notes: the $50-$60K BOM estimate is likely off by a wide margin, and a more true estimate places the cost at $250-450k according to the CEO of Collaborative Robotics. Very few components are off-the-shelf and humanoid components (like the ones in Optimus) are designed for max capability. High-torque actuators are custom-built for torque-to-weight performance, the battery packs are bespoke, and dense compute are all optimized for performance. None of this benefits yet from NRE amortization or a real supply chain.

Interesting Video: How to Boil Water (Really) Fast

Ashlee Vance from Core Memory recently toured Impulse Labs. Skip to 11:00–14:00 for the most relevant section on product development.

The system builds on legacy induction stove components but delivers much higher power, using a silicon carbide FET module in its drive system (the inverter and control circuitry that flips DC to high-frequency AC powering the induction coil) — similar tech to what’s inside EV drivetrains.

The battery pack is lithium iron phosphate (LFP: safer, longer-lasting, lower energy density), assembled via laser welding, and uses prismatic cells (rectangular casing, stackable and easier to integrate). It's co-developed with an unnamed partner, but likely BYD given all the clues.

Manufacturing & Startup News

More leftovers from our weekly research:

Remora retrofitted a 4,400hp diesel locomotive with onboard carbon capture, storing exhaust CO₂ for downstream sequestration or reuse. For context, rail currently moves 40% of U.S freight.

AeroVironment acquired BlueHalo for $4.1B to combine drones with directed energy and satellite comms.

Anduril acquired Klas for edge computing and secure radios as part of developing tactical communications for autonomous systems. Klas’ technology includes ruggedized servers and software-defined radios for defense applications.

Canada approved GE Vernova and Hitachi’s 300MW BWRX-300 reactor, a simpler, passively safe small modular reactor (SMR)

Foundation Alloy raised $7.5M to scale zero-heat mechanical alloying, -effectively stronger metal alloys for defense, aerospace, and tooling applications.

Refer a Friend, Earn Rewards 🎁

Refer just one friend to Hardware FYI, and we’ll send you our complete database of resources—every design guide, article, white paper, and more.

Thanks for reading to the end - if you’ve enjoyed the mechanics of these insights, consider sharing this issue with a fellow enthusiast!