Improvised Manufacturing at Scale

Weekend Wire #51

👋 Happy Saturday! This week’s edition covers a presentation on frontline labs as a new manufacturing layer in modern defense production, a diagram tracing the often overlooked DJI talent diaspora, and a no-nonsense primer on oscilloscope basics.

We’re hosting an online workshop next Wednesday on a novel molding process for electronics hardware design, focused on thermal management, EMI shielding, and scalable manufacturing. And if you’re in San Francisco, we’re hosting our first happy hour of the year on 2/12!

Interesting Presentation: Frontline Labs as a New Manufacturing Layer

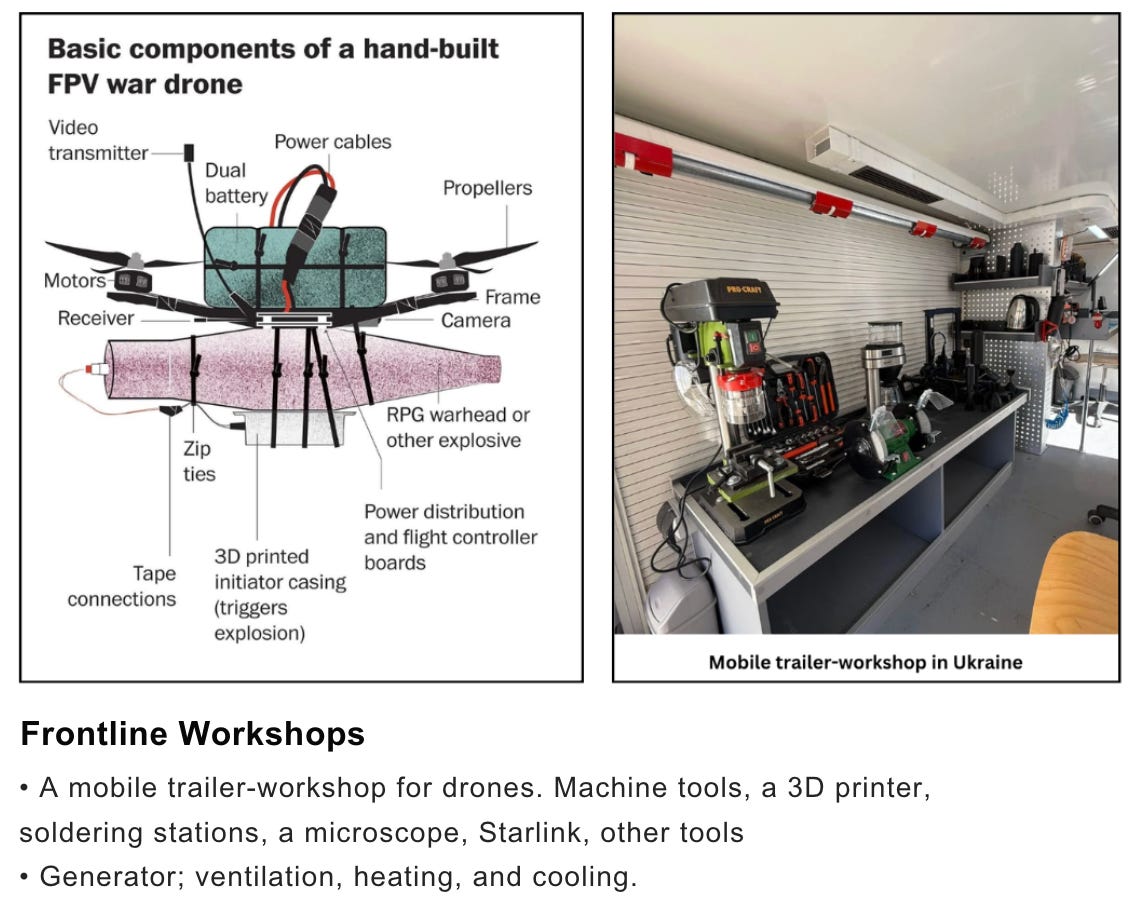

Pulled from a recent presentation by Ukraine’s Arms Monitor, this is a rare look at what modern, distributed manufacturing looks like under extreme constraints. Instead of final integration happening in centralized factories, nearly 100% of drones now pass through a new manufacturing layer known as “frontline labs”, where they’re modified and outfitted with the latest changes just before deployment.

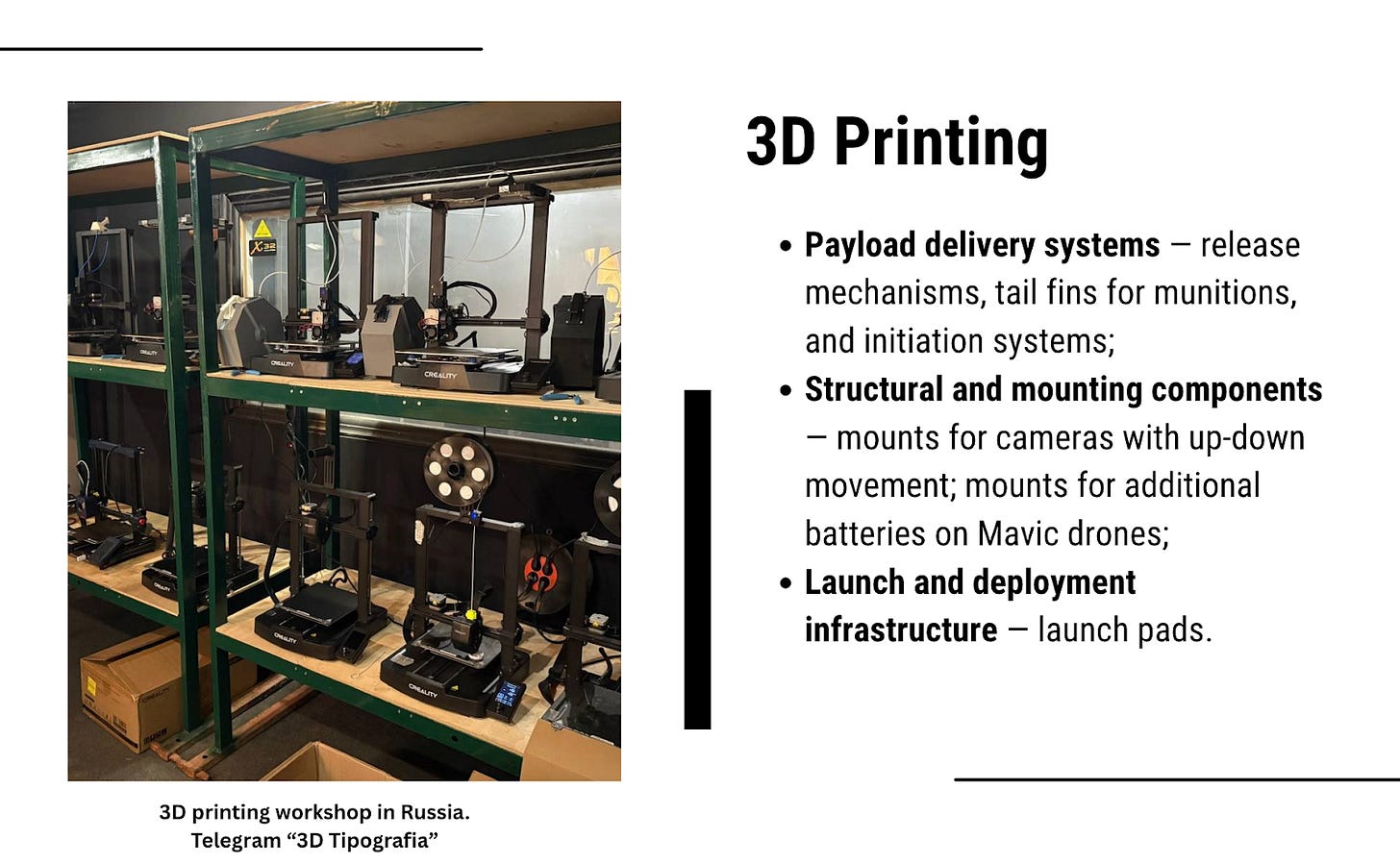

There’s a strange contrast here with trillion-dollar defense ecosystems on one side, and on the other, modern battlefield production built from consumer drones, hobby electronics, and plastic filament. Most of the first-person-view (FPV) drone platforms used for improvised weapons production cost on the order of a few hundred dollars per unit and are assembled from commercially available components. 3D printing is then used for payload customization, including payload release mechanisms, munition tail fins, camera and battery mounts, and initiation housings.

In many ways it points to a different model for defense tech, an idea Harry O’Hanley first mentioned, where systems are shipped in a near-final state and final integration becomes an operational activity.

Interesting Diagram: Don’t Forget the DJI Mafia

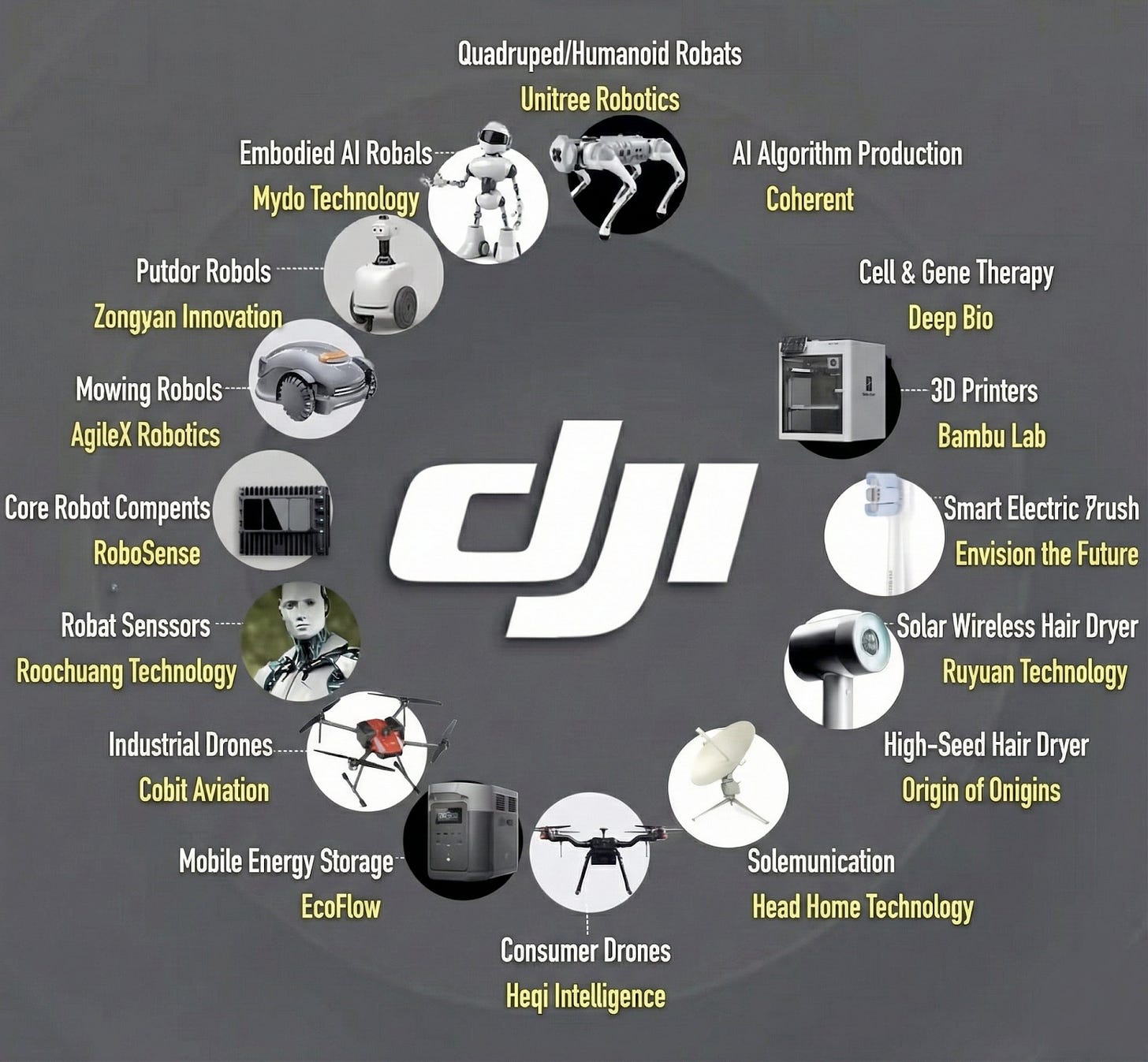

Everyone has heard of the SpaceX mafia, but there’s a similar pattern around DJI that’s easier to miss because it’s international. Many robotics and hardware startups trace back to early DJI teams, including Bambu Lab — the 3D printing company that has quickly become one of, if not the most, popular desktop 3D printer brands. The first five founding members at Bambu Lab were literally all senior leads from DJI’s core product, systems, and controls teams.

Of all the reasons to join early-stage teams, arguably the most important one is meeting the people who go on to build the next generation of companies.

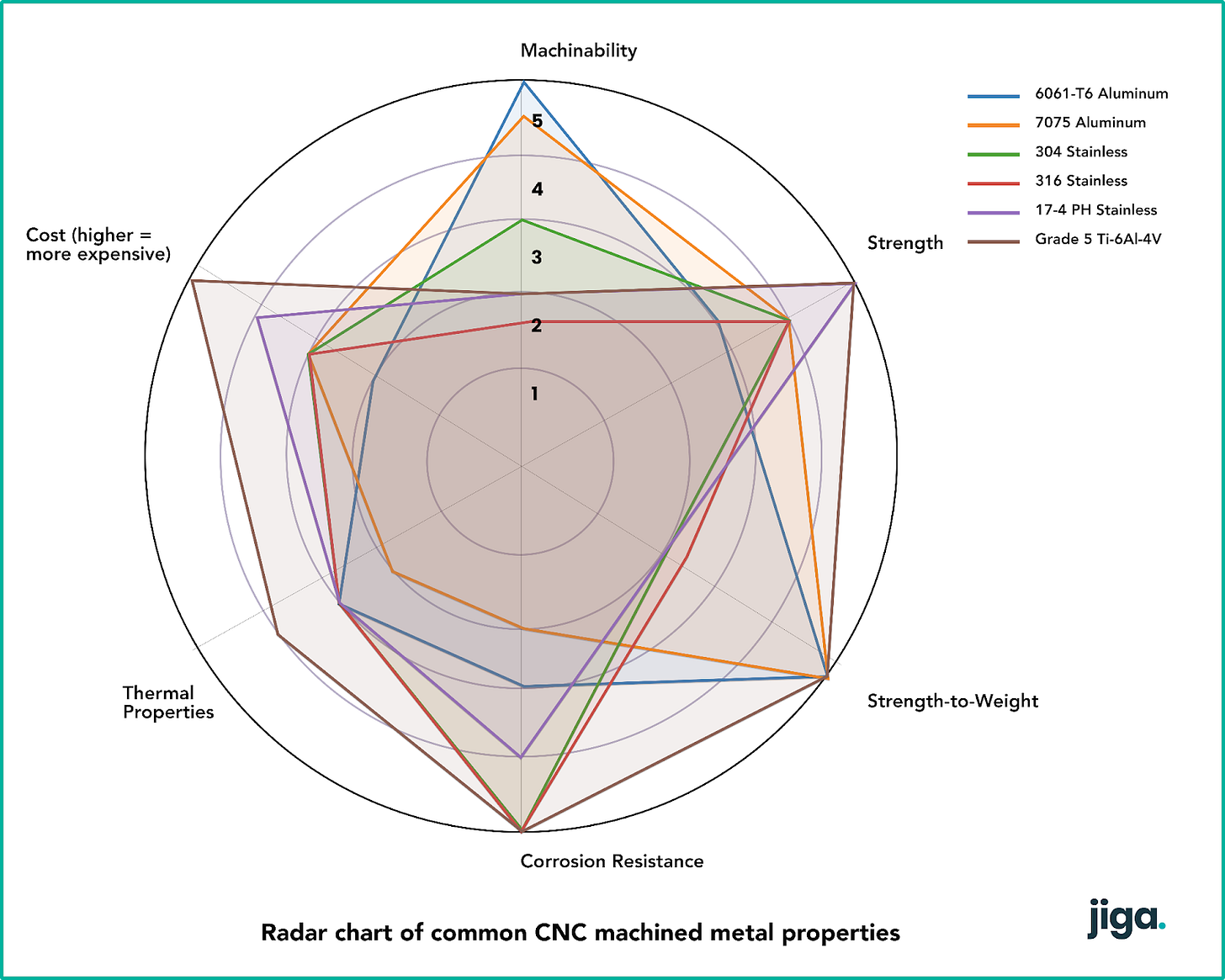

Presented by Jiga: CNC Materials Selection Guide

Material selection affects everything downstream — machinability, lead time, cost, and part performance. Jiga’s CNC machining materials selection guide explains how to match properties to real requirements, avoid common traps, and includes a quick-reference matrix for the most common machining materials.

Interesting Video: Oscilloscope Basics for Beginners

A no-nonsense beginner’s guide to using an oscilloscope. The video covers the basics in the right order across what an oscilloscope does (sampling and displaying a signal over time), bandwidth and sampling, triggering, then measurement and probe setup.

Notably effective use of fast, Gen-Z-style editing to distill dense technical material.

Manufacturing & Startup News

More leftovers from our weekly research:

Canvas, a robotics startup developing worker-controlled drywall finishing systems, was acquired by JLG, bringing on-site construction robotics into a major construction equipment OEM.

Former Google CEO Eric Schmidt is planning to privately fund Lazuli, a next-generation space telescope intended as a more capable successor to Hubble, alongside three large modular ground-based observatories.

Valinor raised $54M in Series A funding just months after emerging from stealth, bringing total funding to $85M to scale its portfolio of defense-focused product companies. The Palantir-alum-founded company is structured as an operational holding company, betting on a distributed model where product subsidiaries own individual systems and a central team handles go-to-market and infrastructure.

GreenPower Motor Company selected Santa Teresa, New Mexico for a new 135,000-sq-ft manufacturing facility and its U.S. headquarters, backed by roughly $15M in state incentives.

And to wrap up the issue, TechCrunch is running a live CES 2026 feed tracking the stream of announcements, demos, and the next wave of AI-infused consumer hardware.

Tools From Our Partners

Flow – Agile requirements management platform for complex systems.

Jiga – Custom parts at digital speed, with trusted shop access.

Zenode – Free AI-powered search engine for electronic components. A smarter, faster alternative to part catalogs like Digi-Key.

Access Every Link We’ve Ever Shared 🎞️

Refer three friends to Hardware FYI and unlock our full archive.

Missed an issue? Hunting for that one link? Every tool, guide, and article we’ve ever shared is in here.

P.S. If you find something interesting—an article, tool, funding round, project, really anything—send it our way!

P.P.S. 17,750+ engineers, founders, and operators read this newsletter. If you want to reach them, get in touch.