Onshape is offering hardware startups and entrepreneurs free access to Onshape Professional or Onshape Government (compliant with ITAR/EAR). Both include CAD, rendering, simulation, PDM, and more. Apply for the program to get started today.

Interesting Links 🏭

Apple in China: The Capture of the World's Greatest Company is a book worth reading for its account of how Apple built the most complex hardware supply chain in the world, anchored almost entirely in China and Southeast Asia. Much has been documented about the creative partnership between Steve Jobs and Jony Ive, but not as much about Tim Cook and Foxconn founder Terry Gou on operational excellence at scale. When the U.S. talks about advanced manufacturing and why it’s so hard to reshore, look no further than this: internal documents showed that Apple’s investments in China reached $55 billion per year by 2015! We recommend reading the book in full, but here are a few specific things we found interesting:

Apple’s hardware org is structured like a pyramid. Industrial Design sits at the top and sets the form, Product Design handles mechanical integration, Manufacturing Design translates it for mass production, and Operations works with vendors to scale and cost-down. A common saying on pushing back against ID was “You’d have to drive the car off the cliff to prove the brakes don’t work.”

The original iMac released in 1998 marked the shift in Apple’s internal hierarchy where industrial design took the lead for product decisions. Design was the differentiation, and the original form pushed so far beyond plastic manufacturing constraints it actually delayed launch by five months.

One of the best primers on reduction systems used in robotics, and how different systems approach the torque-speed tradeoff. Electric motors generate peak power at high speeds (typically several thousand RPM), but robotic joints operate best at low speeds with high torque and fine positional accuracy. Reduction systems bridge that gap by trading speed for torque, and amplifying resolution by gearing down motor motion into precise, controllable output. The post covers planetary gearboxes that stack multiple stages to achieve high reduction (at the cost of cumulative backlash; each gear mesh introduces a small amount of slop that compounds across stages), and strain wave drives (also known as harmonic drives, commonly used in humanoid robots) that use a flexing spline to deliver 30–160:1 reduction with near-zero backlash, but introduce compliance and cost. The Archimedes Drive from IMSystems is a newer, friction-based system that uses spring-loaded metal rollers instead of gears to transmit torque; compact and backlash-free in theory, but whether it sees real adoption remains to be seen.

On the topic of plastic part design, family tooling is a mold design technique that produces multiple different parts in a single injection cycle using a shared mold base. It’s more commonly used for assemblies where parts are paired (like a front and back cover) so the components can be molded together with consistent material properties and color. The tradeoff is added complexity; because each cavity differs in size and geometry, imbalanced mold fill and cooling rates can lead to defects like short shots and shrinkage.

Shippable microfactories are built on the premise that rather than hauling prefabricated panels or modules across the country, bring a containerized factory to the jobsite to produce components on-site. Traditional factories are capital-intensive and depend on steady high-volume throughput where any dip in utilization drives up unit costs. In theory, microfactories should cut CapEx and maintain high usage through project-based deployment while driving down cost. Early examples are emerging: AUAR built a two-story office in Belgium using a pop-up robotic cell inside a shipping container, and Cuby operates deployable $10-15M microfactories for housing production. Volumes remain low, typically on the order of tens of units.

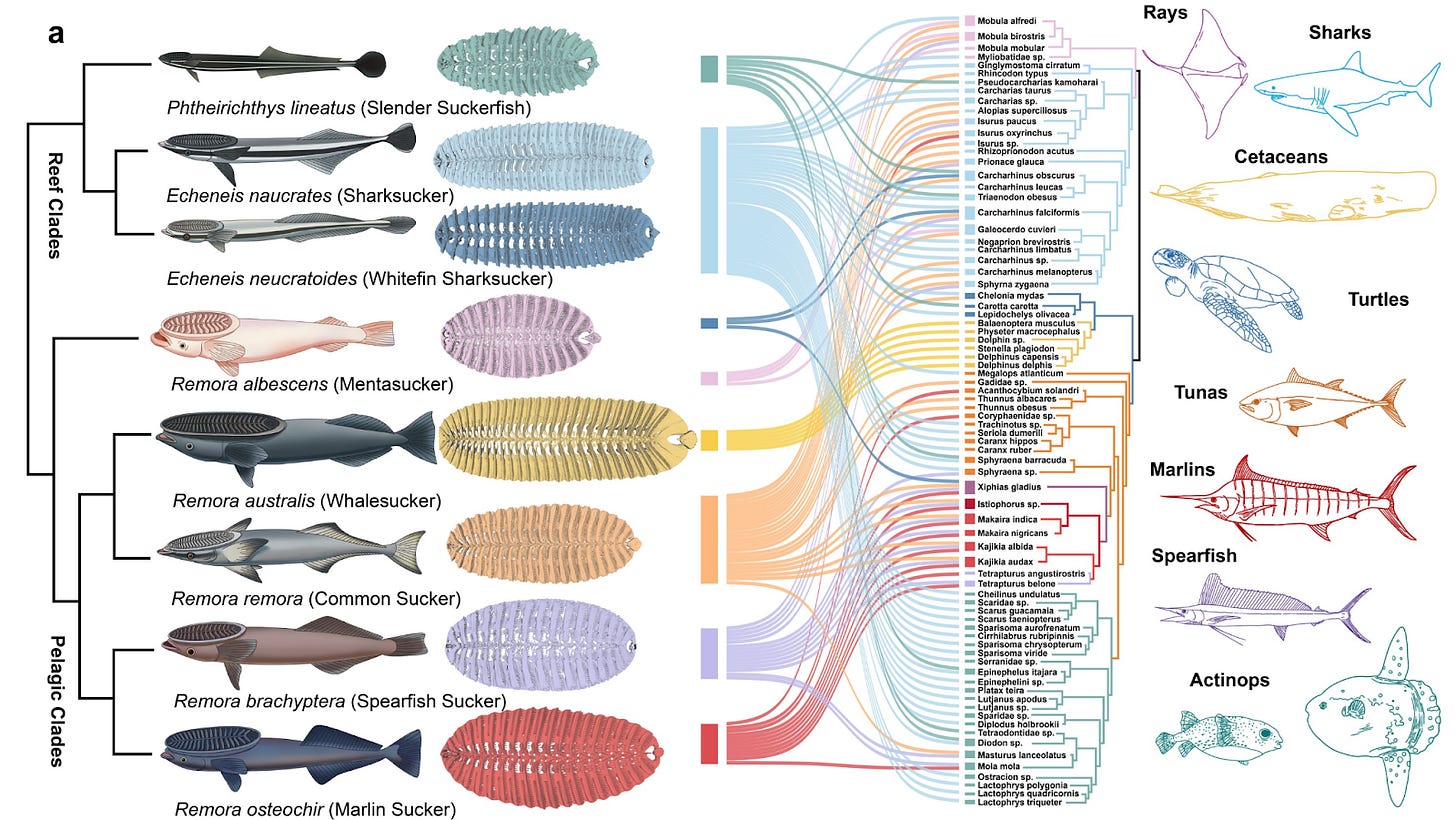

Who sucks on what? This chart shows which species of remora (a fish with a suction disc on its head) are able to attach to which species of host. Scientists recently mimicked the adhesive disc of remora fish to develop the Mechanical Underwater Soft Adhesion System (MUSAS), designed for strong attachment to soft, moving surfaces. It uses angled, heat-responsive metal plates (shape memory alloy lamellae) and soft, flexible elastomer compartments to maintain grip on surfaces with varying stiffness, roughness, and pH. Validated in vivo, it’s been tested for applications like aquatic temperature sensing, non-invasive GERD monitoring, and sustained HIV drug delivery.

A couple fun links:

If you're building a factory, this is a great thread on finding space, checking utilities, and figuring out financing.

A reference on visual aesthetic principles used in industrial design.

Our SF Hardware Happy Hour is happening on 8/28. Free foods, free drinks and good people to talk shop - check it out here.

Sponsored: A technical whitepaper from nTop on using implicit modeling in early-stage aircraft design.

Startup News 🚀

Raise Robotics secured $7.75M in seed funding to expand its AI-powered construction robotics platform which automates high-risk, repetitive tasks on job sites. The company’s mobile system uses interchangeable tools for layout, drilling, and scanning, with a recent deployment on a 15-story St. Jude hospital project. MaC Venture Capital led the round.

Joby Aviation and L3Harris Technologies are teaming up to build a gas turbine hybrid VTOL aircraft designed for low-altitude defense missions. It’ll be optionally piloted, combining Joby’s electric VTOL platform and autonomy stack (from Xwing) with L3Harris’ experience integrating sensors and comms systems. Flight tests start this fall, with operational demos planned for 2026.

OpenAI is launching its first European AI data center in Norway with a joint venture committing $1B each from partners for the initial 20 MW phase, scaling to 290 MW and 100,000 Nvidia GPUs. The facility plans to utilize renewable hydropower, direct-to-chip liquid cooling, and heat repurposing for low-carbon industries.

SixSense raised $8.5M in Series A funding for its no-code AI platform that helps fabs detect defects and predict failures in real time. Their platform has already been deployed at GlobalFoundries and JCET, processing over 100M chips and reduced manual inspection by 90%. The Singapore-based startup is expanding into the U.S. as new fabs come online globally. Peak XV’s Surge led the round.

SunCubes raised $1.2M in seed funding to commercialize long-range laser charging for indefinite drone flight via adaptive optics and photovoltaic tiles. The system supports 10 kW ground stations, providing beam-steering technologies for wireless power transfer in inspection and UAV applications. The round was co-led by RoboIT and CrossConnect.

Open Jobs 💼

More jobs added weekly on our job board. If you're hiring, promote your open role here.

Sponsored:

Dirac is hiring a Fullstack Engineer and a Marketing & Growth role to build automated work instructions in NYC.

Early Career:

Hadrian is looking for a Design Engineer, Special Projects in Los Angeles, CA

Mid-Level:

Persona AI is looking for an Electrical Engineer & Product Design Engineer in Houston, TX

Fleet Robotics is looking for a Mechanical Engineer (Underwater Robotics) in Boston, MA

Senior to Staff:

SharkNinja is looking for a Director (Advanced Development) in Needham, MA

Lucid Motors is looking for a Staff Global Supply Manager in Newark, CA

Internships:

Cobot is looking for a Robotics Assistant in Santa Clara, CA

Tools From Our Sponsors

Manufacturing

Loombotic - Instant-quote custom wire harnesses. Upload drawings or design online, fast turnaround.

Summit Interconnect – Quick-turn complex rigid, flex, and rigid-flex PCBs.

Fictiv – On-demand custom manufacturing from prototype to production.

Formlabs Fuse – Office-ready SLS printer for in-house nylon production with industrial part quality.

Design & Simulation

Quilter – Fully automates PCB layout with physics-driven AI.

nTop – Computational design to accelerate product development.

Onshape – Cloud CAD with real-time collaboration and version control.

Dystr – AI math environment that slashes analysis time 10–100×.

Ops & Collaboration

Dirac – Work instructions, automated. Context-aware production planning starts here.

Doss – Adaptive ERP for orders, inventory, and production.

AllSpice – Git-style revision control for hardware designs.

If you're prepping for interviews, we've put together practical resources for engineers. For all resources available, check our home page.

Access Every Link We’ve Ever Shared 🎞️

Refer three friends to Hardware FYI and unlock our full archive.

Missed an issue? Hunting for that one link? Every tool, guide, and article we’ve ever shared is in here.

Reading 'Apple in China' was such a great insight on how manufacturing at Apple evolved to what it is today. I only wish the iMac Toaster Line in Wales ended up being a successful venture!