👋 Happy Saturday! This week’s highlights include lecture notes on textile manufacturing, a chart on next-gen nuclear reactor types, and a hands-on walkthrough of how one founder bootstrapped a hardware product to $210K+ in first-year revenue.

Interesting Lecture Notes: How Textiles Are Engineered

Most people think of textiles as soft goods—clothes, upholstery, and maybe the occasional piece of technical fabric. But under the hood, textile manufacturing is a set of highly engineered, mechanical processes, often running on machines as complex and fast as any CNC mill.

Carbon fiber, for example, before it becomes an aerospace-grade composite, starts out like fabric: pliable, drapeable, and handled on rolls. (Many composite parts begin as textile-based fiber preforms similar to soft goods but only with structural intent.)

This 2019 Stanford lecture on textiles explores how centuries-old manual techniques (knitting, weaving, braiding) have evolved into today’s fully automated manufacturing systems.

Weaving: Involves interlacing two sets of yarns, warp (vertical, fixed yarns) and weft (horizontal, inserted yarns) at right angles to create a flat, structured fabric. Typically done on a loom that holds the warp yarns under tension while the weft is passed over and under them in specific patterns. Produces strong, stable fabrics like denim or cotton shirts but with limited stretch unless elastic fibers are used.

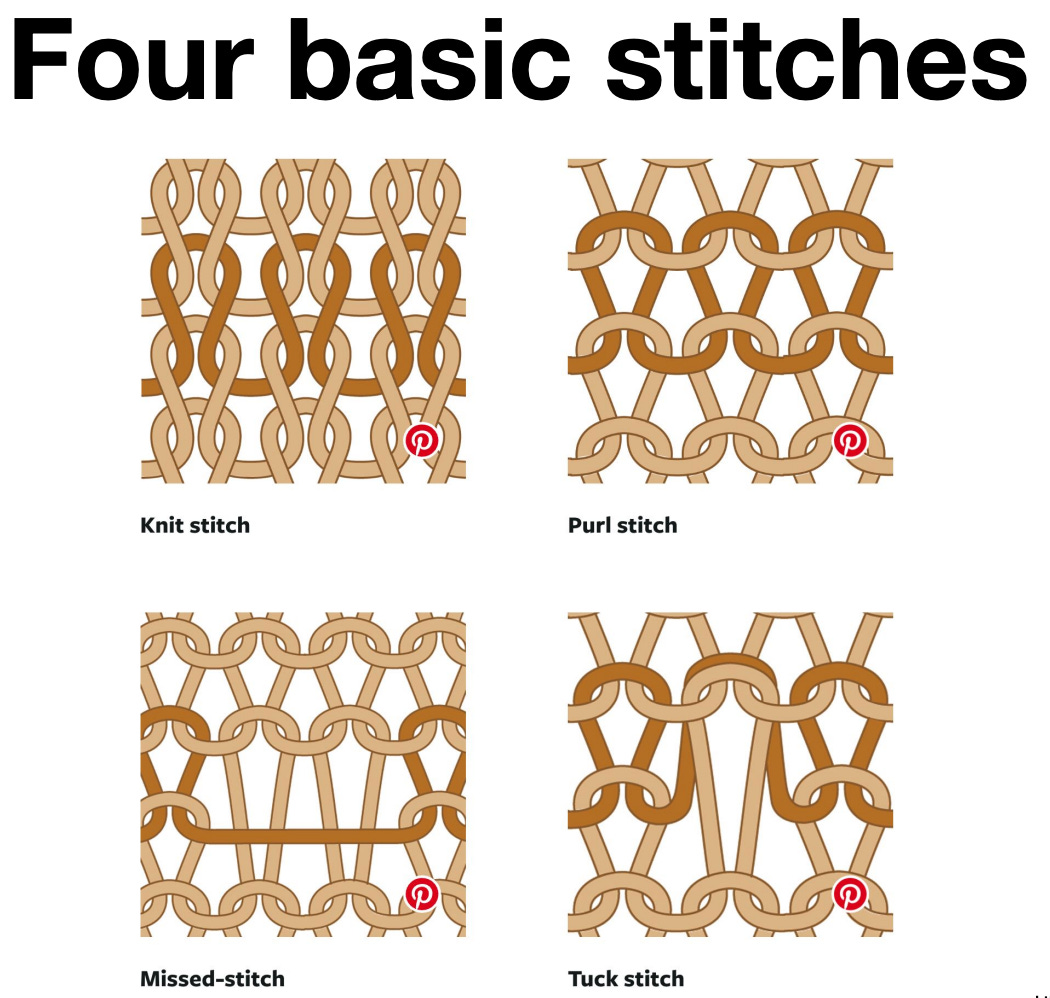

Knitting: Creates fabric by interlocking loops of a single yarn or multiple yarns either by hand or machine. Two main methods: weft knitting (yarn moves horizontally forming rows of loops) and warp knitting (yarns zigzag vertically forming columns).

Braiding: Interlaces three or more yarns diagonally in a crisscross pattern to form a rope-like or flat structure. Unlike weaving, yarns follow continuous, intersecting paths without the need for a loom. Produces narrow, strong structures like robes, cables, and protective sleeving.

Interesting Chart: Types of Gen IV Nuclear Reactors in Development

An overview of next-gen. (Gen IV) nuclear fission reactor types under development. Examples in the works include Radiant (high-temperature gas reactor), Terrestrial Energy (molten salt reactor), and Aalo (liquid-metal fast reactor).

Interesting Video: From Prototype to $210K+ in Hardware Sales

This might be the single best introductory walkthrough covering how to build and ship a hardware product with zero existing context. Some background: a new college grad studying Mechanical Engineering, with no prior hardware experience, decides to build a heated massager for people with jaw pain. Taught himself PCB design in EasyEDA starting with a functional block diagram, then selecting components, and finally translating it into schematic capture and layout.

He also walks through real-world failure modes like thermal runaway and electrical noise, and how he addressed them using safety features found in production hardware: watchdog timers, thermal fuses, and crowbar circuits. All while bootstrapping from his apartment. Here are the results from the past twelve months:

$210,000 in revenue (~1,000 units sold)

~$110,000 in profit, with extra inventory on hand after:

$37,000 spent on raw materials and components

$30,000 invested into ads

$33,000 startup costs (including 3D printers, certifications, rent, and legal)

Manufacturing & Startup News

More leftovers from our weekly research:

Space Forge raised a $30.4M Series A round to launch ForgeStar-1, a reusable satellite designed to manufacture high-performance materials in microgravity and return them to Earth.

Canadian-based Svante opened a 141,000 sq. ft gigafactory to capture 10M tons of CO2 yearly.

Solestial raised a $17M Series A round to scale low-cost, space-grade silicon solar panels for long-duration missions in LEO and beyond.

Realta Fusion raised a $36M Series A round to build a compact magnetic-mirror reactor by 2028, aiming to power next-gen compute loads.

Zeno Power raised a $50M Series B round to develop nuclear batteries for space and remote ops, with first deployments expected by 2027.

Refer a Friend, Earn Rewards 🎁

Refer just one friend to Hardware FYI, and we’ll send you our complete database of resources—every design guide, article, white paper, and more.

Thanks for reading to the end - if you’ve enjoyed the mechanics of these insights, consider sharing this issue with a fellow enthusiast!

Textile engineering is so fascinating! As an ME undergrad, I was a researcher for the Design of Active Materials and Structures Lab at the University of Minnesota, and they're doing super interesting work on smart textiles (primarily with Nitinol). It's wild how much the weave/knit/stitch affects the mechanical properties!