The Expensive Part Is the Mold

Weekend Wire #39

👋 Happy Saturday! This week’s highlights include lecture notes on mold design, a reference on standard lathe operations, and two videos from opposite ends of the tooling spectrum—one on nibbling sheet metal and the other on how chips are made using EUV lithography.

P.S. We’re hosting an online workshop on factory site selection (think playbooks on how high-growth manufacturers and startups decide where to build). And if you’re in San Francisco, we’re running it back with another happy hour in November.

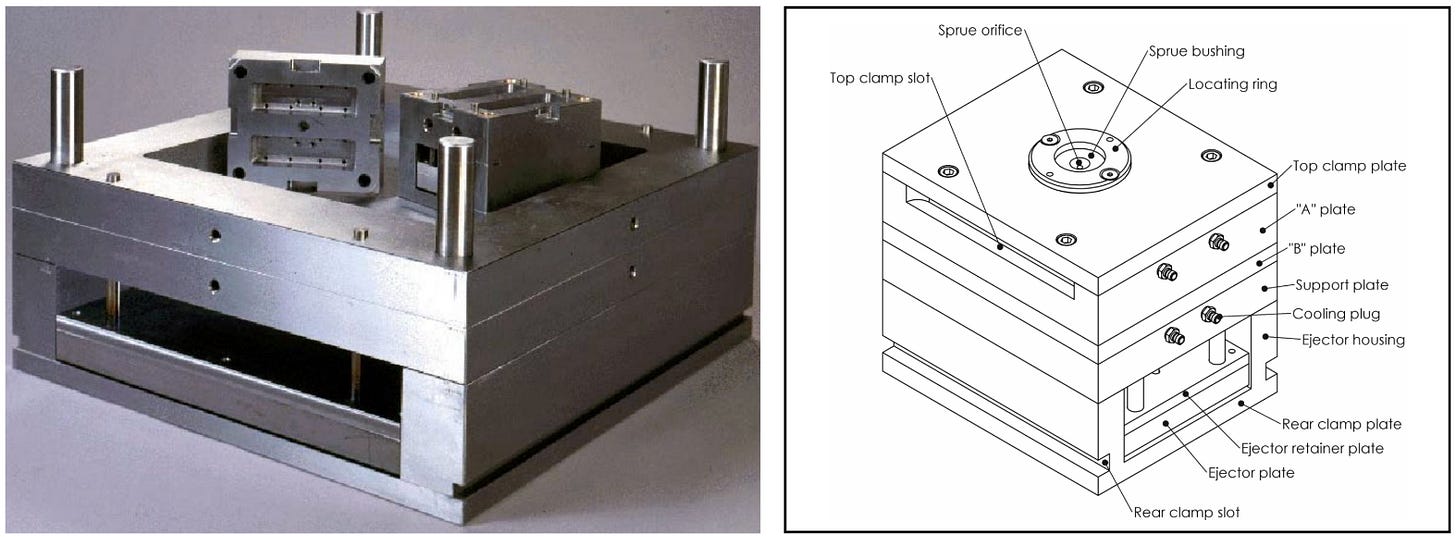

Interesting Lecture Notes: An Introduction to Mold Design

This week’s lecture from a Texas A&M course on injection molding design is a great primer on the physical realities of tooling, and why seemingly small design choices can become the most expensive part of a program. Mold design is part shop-floor craftsmanship married to engineering, and less about abstract design theory and more about what mold makers actually do to turn a CAD model into hardened steel.

Every injection-molded part starts with tooling and it’s a significant fixed startup cost: a simple two-plate mold can run thousands or tens of thousands of dollars, while multi-cavity or hot-runner systems climb well into six figures depending on part complexity.

In practice, it’s a sequence of shop-floor operations that turn blocks of steel into a working tool:

Cutting the core and cavity: The mold starts with steel blocks that get cut by CNC mills or EDM, leaving the negative of the part.

Adding cooling lines: Holes are drilled for water channels that keep parts cooling evenly and cycle times short.

Building the ejection system: Pins, sleeves, or plates that push finished parts off the mold without damage.

Surface finish and polishing: Polishing and texturing guide how plastic flows and how the finished surface looks.

Balancing gates and runners: The paths for molten plastic; their size and placement determine if you get clean parts or defects.

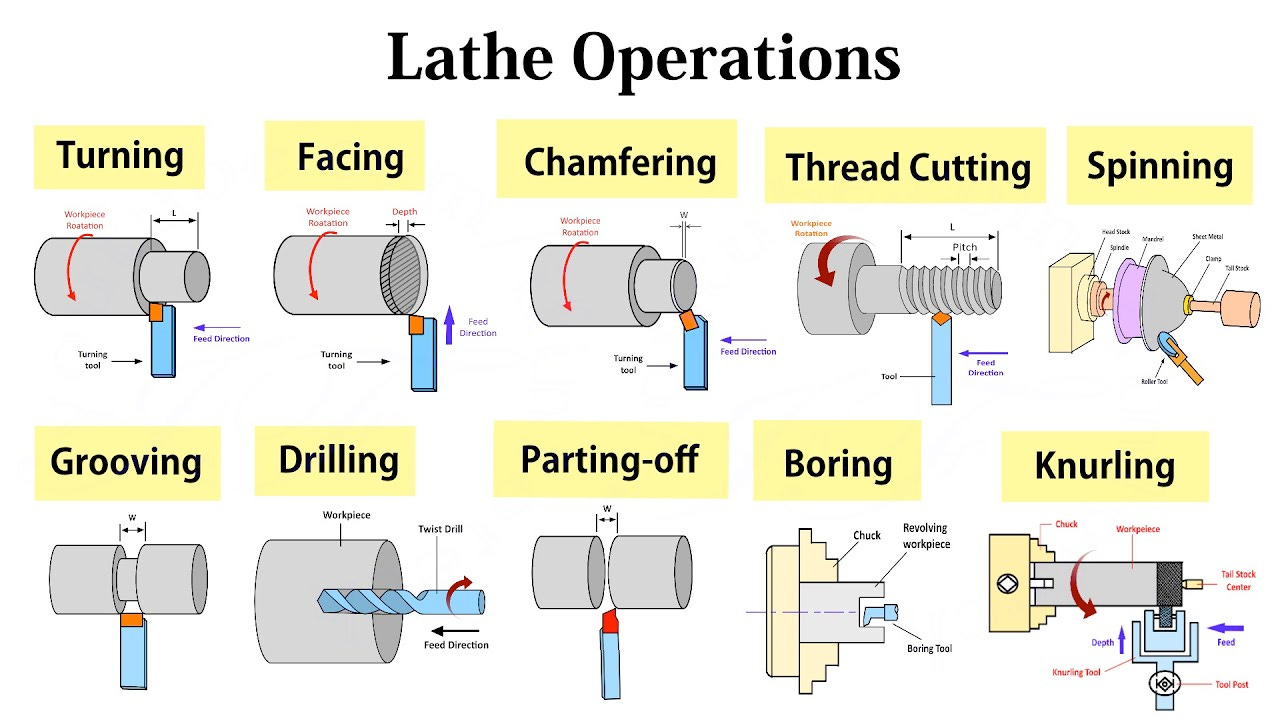

Interesting Chart: Types of Lathe Operations

A reference on ten standard lathe operations that involve shaping, cutting, and finishing rotating cylindrical workpieces. At the end of the day, it’s really just: spin the workpiece and press a sharp tool into it.

How it looks in practice on a CNC lathe here.

Interesting Video: Nibbling Metal & Printing Chips

Two videos to round out our manufacturing focus this weekend:

First, a tool worth knowing about: a nibbler (like the Milwaukee M12) is a handheld punch press that instead of shearing the panel in one pass, takes a series of small bites (punch through die) and shears out crescent-shaped slugs of material. Not fast or glamorous, but a neat example of the many different ways to cut through sheet metal.

Second, a clear visual explainer of how EUV lithography actually works to make the wafers that become the chips inside your phone. ASML also has a great video walking through the process in their EUV scanners, among the most complex machines ever built.

Manufacturing & Startup News

More leftovers from our weekly research:

Axon is acquiring Prepared, an AI platform that synthesizes 911 call data (audio, video, GPS) into intelligence for faster public safety responses within Axon’s ecosystem.

Empower Semiconductor raised $140M in Series D funding for SoCs with integrated voltage regulators, targeting high-density power in AI and data center applications.

The Pentagon awarded $25M to IperionX to support a $75M expansion of its Virginia titanium campus, scaling to 1,400-ton annual powder capacity via HAMR and HSPT processes for lower-energy aerospace and defense parts.

Pacific Fusion announced a New Mexico R&D and manufacturing campus for pulsed magnetic fusion systems, aiming for net gain by 2030 and commercial deployment in the mid-2030s at 100× performance and lower cost.

Nscale raised $1.1B in Series B funding to expand its AI-native infrastructure integrating compute, networking, storage, and services. It’s the largest Series B in European history.

DEXA closed the final tranche of its $15M seed round to expand at-home drone delivery in major U.S. cities. The company operates its own certified DE-2020 hexacopter and holds a nationwide waiver to fly beyond visual line of sight (BVLOS).

Just for fun: the former Head of Surgery Engineering at Neuralink is running a six-week “bring your own project” style accelerator through her boutique consultancy. Applications close 10/6 - check it out here.

Tools From Our Sponsors

Flow – Agile requirements management platform for complex systems.

Jiga – Custom parts at digital speed, with trusted shop access.

Zenode – Free AI-powered search engine for electronic components. A smarter, faster alternative to part catalogs like Digi-Key.

Access Every Link We’ve Ever Shared 🎞️

Refer three friends to Hardware FYI and unlock our full archive.

Missed an issue? Hunting for that one link? Every tool, guide, and article we’ve ever shared is in here.

Thanks for reading to the end - if you’ve enjoyed the mechanics of these insights, consider sharing this issue with a fellow enthusiast!

15,000+ engineers, founders, and operators read this newsletter. If you want to reach them, get in touch.