👋 Happy holidays! This weekend’s highlights include a discussion about footwear manufacturing, vertical integration vs outsourcing, and news in the autonomous vehicle sector.

This will be the last newsletter of the year. We’ll be back on Tuesday, Jan. 7, 2025.

🎁 Holiday Gifts: A Primer on Sneaker Manufacturing

One of our favorite aspects of engineering is how often it builds on the past. The evolution of sneakers is a perfect example of the slow melding of discrete industries and how engineering transforms what we wear and use every day.

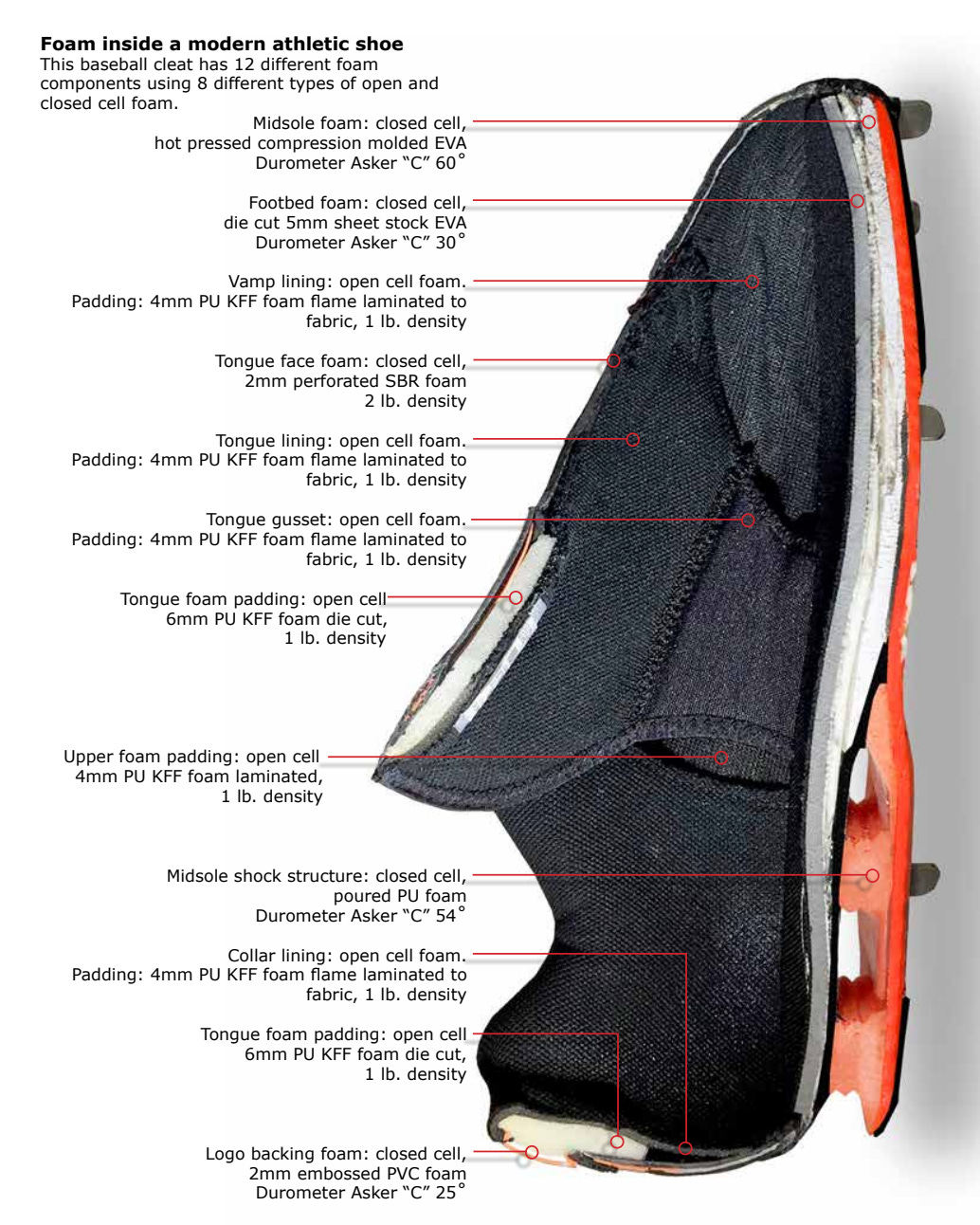

Shoe cushioning is all about solving a simple but critical problem: how to absorb impact without sacrificing comfort or durability. Whether it’s for running, jumping, or everyday movement, most designs fall into two categories: air-soled and non-air-soled systems.

Non-Air Soled Systems:

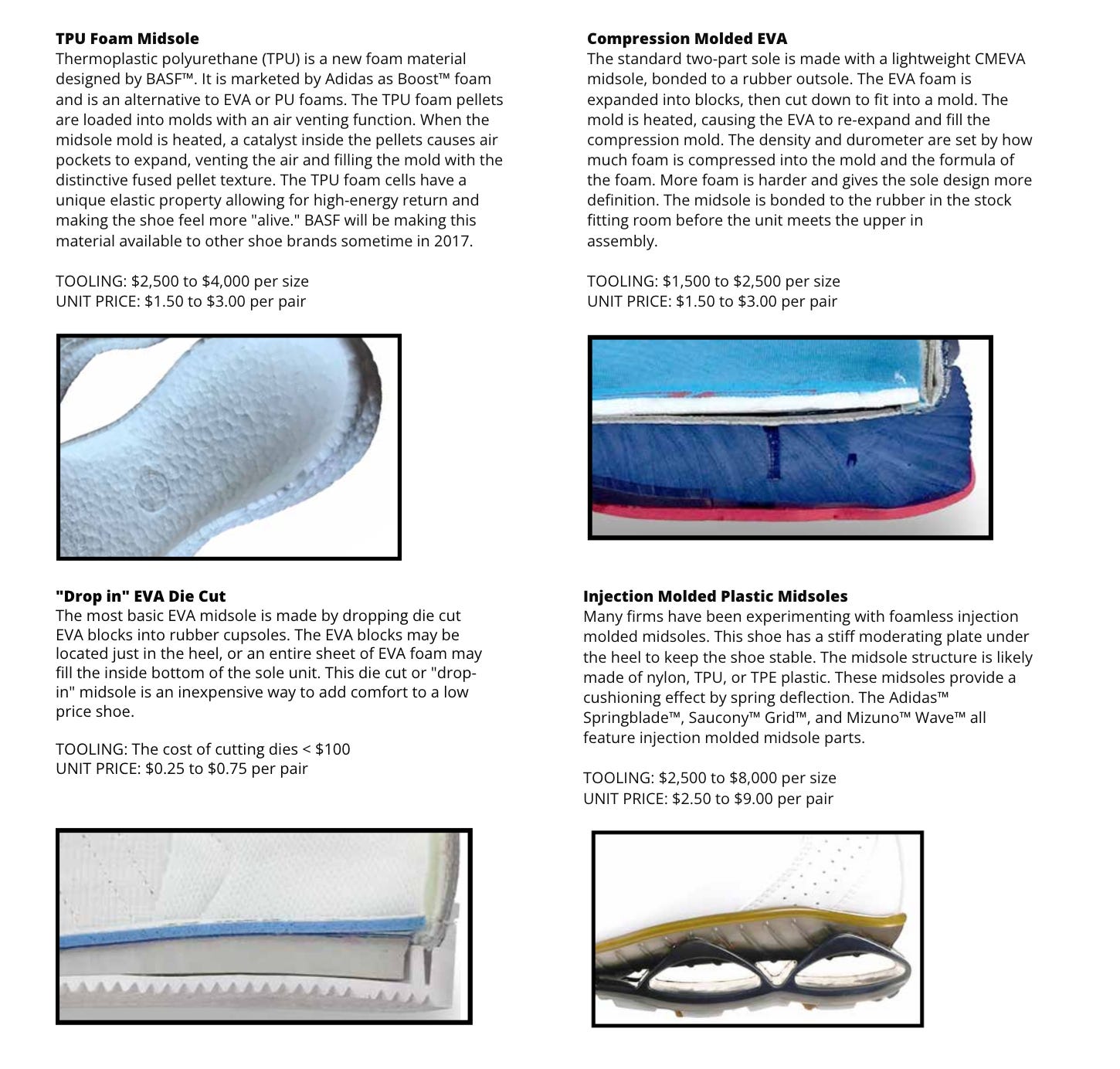

Foams - common materials include EVA (ethylene-vinyl acetate), polyurethane, and thermoplastic polyurethane. Foams used in footwear are typically made from elastomers, where manufacturers directly die-cut sheet stock or use hot/cold-press compression molding to form specific shapes. If you’re a footwear designer, performance attributes used to evaluate foams include measures of foam density, durometer rating (i.e., resistance to surface penetration), and compression set resistance.

The Shoe Material Design Guide provides a great breakdown of common implementations broken down by tooling and unit price for common midsole materials for shoes you’re likely wearing or have worn in the past!

Air-Soled Systems:

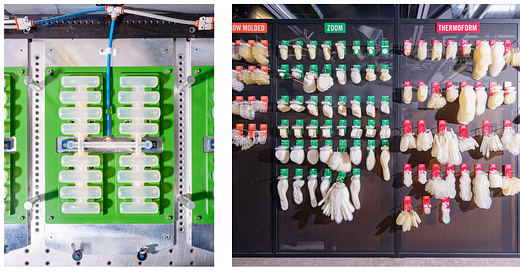

Blow molded thermoplastic polyurethane (TPU). The process is relatively straightforward: two TPU sheets are heated, molded into airtight shells, filled with nitrogen, and trimmed to shape. Specifically, air-soled systems use the same blow molding technique used to manufacture plastic water bottles, but instead use elastic TPU compared to a rigid PET plastic.

Nike was the first to introduce the technology in the 1970’s, which built upon the work of an engineer working for NASA who discovered that encapsulating dense gases within rubber membranes could create lightweight, high-cushioning structures. Full details on the original patent application from 1978 which describes methods for fitting a gas filled membrane in the sole of shoes (US4183156A: Insole construction for articles of footwear).

Fun fact: Nike’s air cushioning system initially used hexafluoroethane (Freon 116) and sulfur hexafluoride (SF6), selected for their inert and non-flammable properties. By 1989, Nike standardized on SF6 due to its stability and suitability for maintaining pressure within Air units. There was a catch though—SF6 turned out to be a potent greenhouse gas, with a global warming potential 23,500 times that of CO2 and a long atmospheric lifespan, which is why the shoe manufacturer transitioned to using nitrogen.

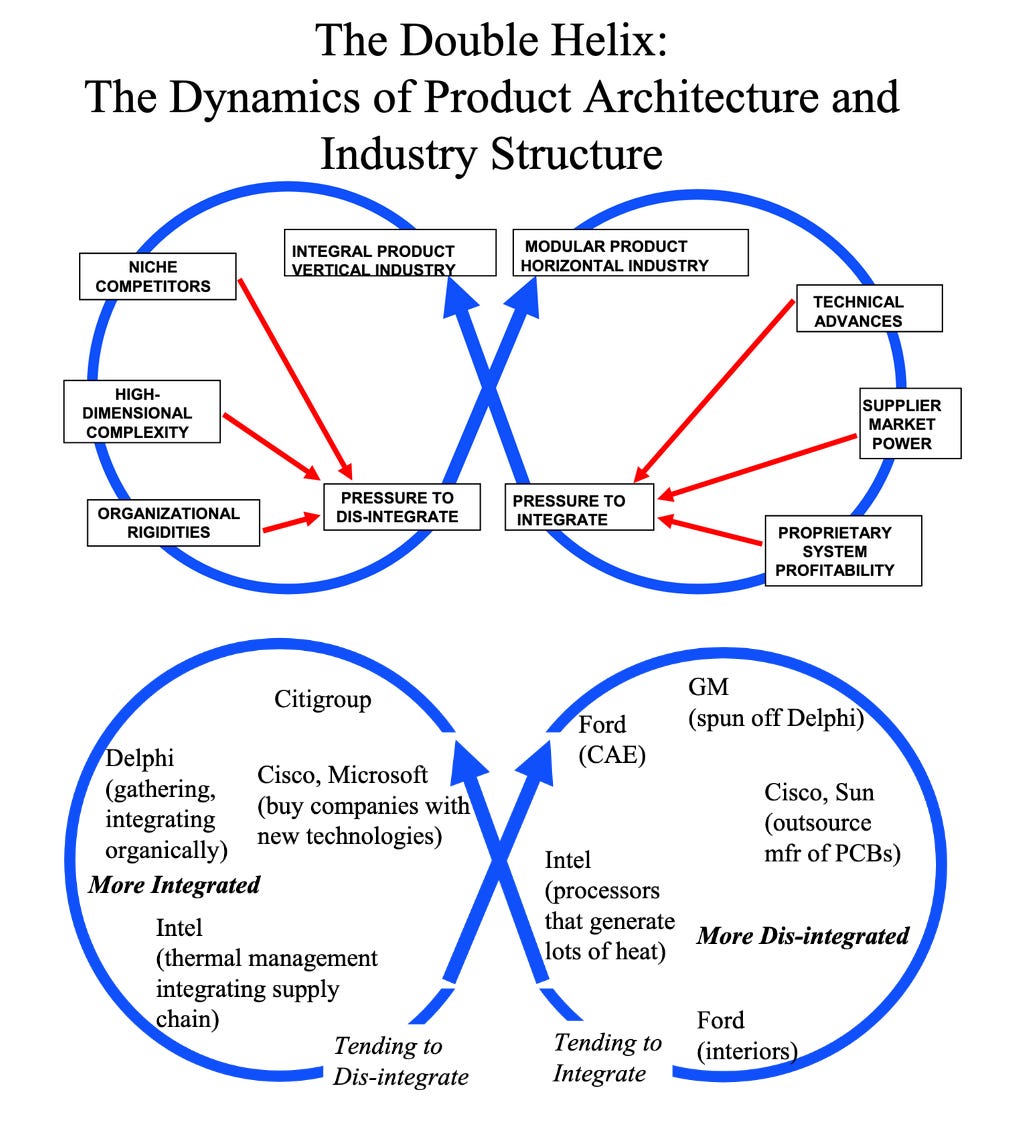

📝 Lecture Notes: Make vs. Buy Criteria

MIT - Is The Make/Buy Decision a Core Competence?

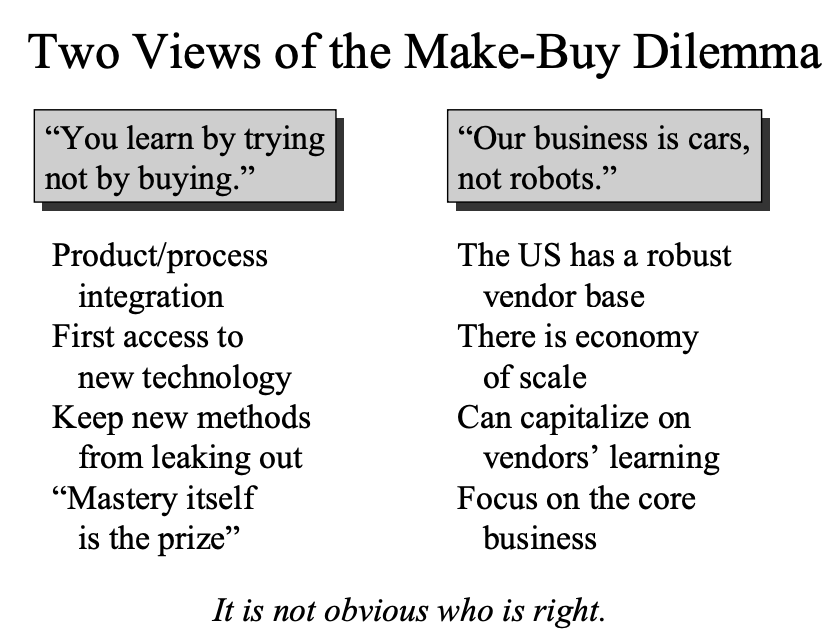

The make-or-buy decision revolves around whether to outsource production to external suppliers or pursue vertical integration by producing in-house. Outsourcing can reduce costs, increase flexibility, and leverage supplier expertise but creates dependency on external parties and potential supply chain risks. Vertical integration offers greater control over quality, costs, and supply chain reliability but requires significant investment and may reduce flexibility in adapting to market changes. “It is not obvious which is right”.

⛐ In the News: General Motors Shuts Down Cruise

Cruise, founded in 2013 and acquired by General Motors for over $1 billion in 2016, has struggled over the past few years grappling with the challenge of bringing its lounge-on-wheels Origin robotaxi into production and navigating setbacks, including the suspension of its robotaxi fleet in October 2023. After investing nearly $10 billion over eight years, GM announced plans to shut down Cruise and integrate it with its technical teams, narrowing its focus to autonomous and driver-assistance technologies for consumer vehicles.

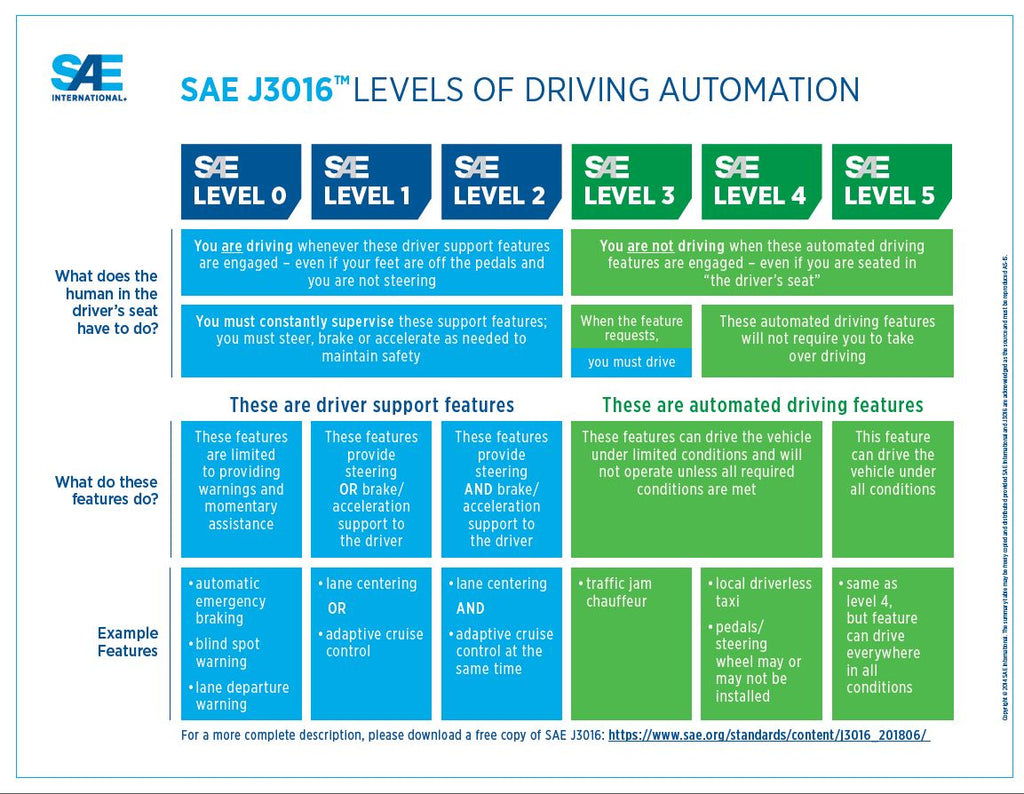

The scope of the work is considerably smaller: Super Cruise is a Level 2 semi-autonomous ADAS system available on 20 GM vehicles. Before shutting down, Cruise was operating a fleet of Level 4 robotaxis to a limited portion of the public in San Francisco from 2022 to 2023.