👋 Happy Saturday! This week’s edition includes a breakdown on how server rail suppliers for GPUs make more profit than Nvidia itself, lecture notes on metal casting fundamentals, and a full build walkthrough of linear motor manufacturing.

Interesting Chart: The Most Profitable Part of Nvidia’s AI Server Isn’t the GPU

A lesson in being a commodity to a much larger market: the most profitable component in Nvidia’s AI server isn’t the GPU, but the server rail kit. From SemiAnalysis, a great analysis of the gross margin of Nvidia compared to Kingslide, a Taiwanese supplier that makes the custom rail kits used to rack and service heavy AI servers inside hyperscaler data centers.

Server rail kits are simple mechanical assemblies — sliding rails that let technicians pull servers in and out of racks for maintenance. Kingslide originally began as a furniture hardware manufacturer (drawer slides and hinges, a business it still operates today) before applying the same expertise to server rails.

Normally, they’re commodity parts, but AI servers are much heavier. Each DGX H100 node (Nvidia’s flagship for training and inference on workloads like LLMs) packs 8 GPUs and weighs over 130 kg. Full racks with 4 or more nodes hold 32+ GPUs, pushing total rack weight well beyond standard CPU servers.

Combine a ~10x higher average selling price for AI server rail kits with Kingslide’s patent chokehold (5,000+ patents covering hole placements and dimensions), and you get the kind of pricing power that drives gross margins into the mid-70% range.

Interesting Lecture Notes: Metal Casting Fundamentals

This MIT lecture covers the fundamentals of metal casting, one of the oldest manufacturing processes dating back to 3200 BC. At its core, casting simply involves pouring molten metal into a mold to form a part, using materials like aluminum, iron, steel, and bronze.

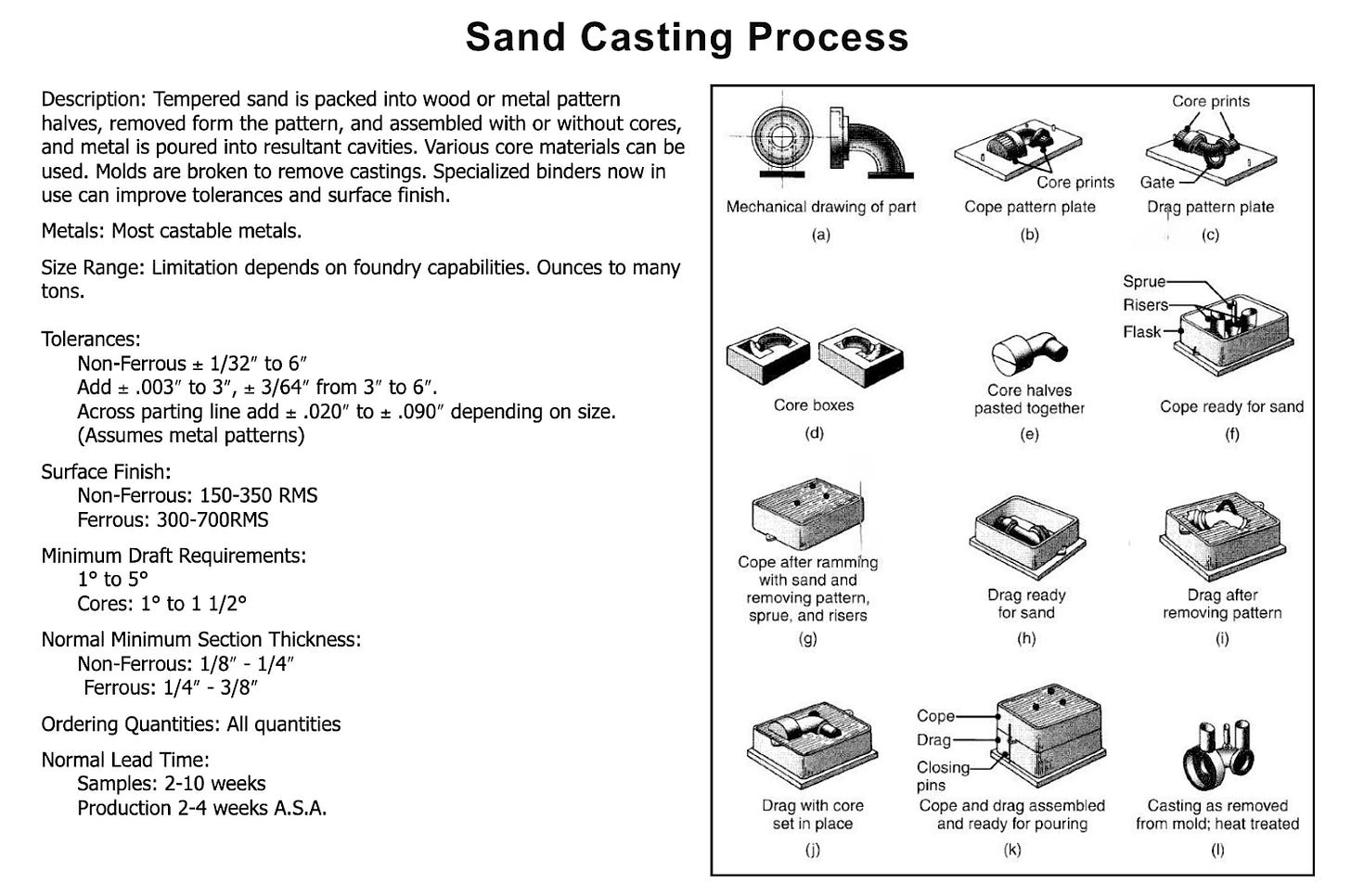

Sand Casting: Sand is packed around a pattern (removed before pouring) to form a cavity, filled with metal, then broken away after cooling. Molds are single-use.

Investment Casting: Wax patterns are coated in ceramic, melted out, then filled with metal. Good for complex shapes. Lower tooling cost than die casting, but slower cycle times. Common in aerospace, medical, and low-to-medium volumes.

Startups like Rangeview are rethinking the front-half of the workflow by binder jet 3D-printing full ceramic shells directly from CAD, replacing wax patterns and dip-coating.

Die Casting: Molten metal is injected into a set of dies under pressure. High tooling cost, but fast and repeatable. Best for high-volume parts with simple-to-moderate geometry. Highly suggest reviewing Fictiv’s design guide for die casting.

One thing we didn’t know until today: sand casting actually still accounts for over 40% of total metal casting revenue, mostly for engine blocks, pump housings, and heavy industrial parts. But in practice, most design work comes down to designing for die casting (~27%) or investment casting (~17%).

A Road Trip to Meet U.S. Manufacturers

Zach from Doss is driving through LA, Chicago, Detroit, Cleveland, and a few smaller towns on a roadshow to meet local manufacturers. He’s documenting what makes American manufacturing great. If you run a value added shop, he’s putting on happy hours in each location, hit him up!

We’re also hosting a manufacturing happy hour in LA (Orange County). Open invite if you want to talk reindustrialization and where the work actually happens. Register here.

Interesting Video: Inside a Linear Motor Factory

The full build sequence behind a linear motor actuator: stator winding, assembly, and potting. Short version available for the impatient.

Manufacturing & Startup News

More leftovers from our weekly research:

Rocket Lab has acquired Geost, a company specializing in electro-optical and infrared sensor payloads for satellites, for $275M. The acquisition aims to enhance Rocket Lab's capabilities in the payload market by integrating Geost's sensor technology into their satellite systems.

Neuralink has secured $600M in funding, raising its valuation to $9B. The funding will support the development and clinical testing of its brain-computer interface implants, which have received FDA "breakthrough" designation for treating conditions like spinal cord injuries.

Glacier, a startup developing automated recycling systems with robots and AI, has raised $16M in Series A funding to expand its robot recycling fleet.

Exterra Carbon Solutions has raised $14.5M to develop its technology for converting asbestos mine tailings into sustainable materials and to build a large processing facility in Quebec. The company aims to transform mining waste into valuable products like nickel concentrate and amorphous silica.

Arrive AI has raised $40M in funding to support its autonomous last-mile delivery platform, which uses drones, ground robots, or human couriers to deliver to smart mailboxes.

Serve Robotics, a company developing sidewalk delivery robots, has raised $80M to scale its operations from 100 to 2,000 robots across U.S. cities by the end of the year.

Refer a Friend, Earn Rewards 🎁

Refer just one friend to Hardware FYI, and we’ll send you our complete database of resources—every design guide, article, white paper, and more.

Thanks for reading to the end - if you’ve enjoyed the mechanics of these insights, consider sharing this issue with a fellow enthusiast!

"One thing we didn’t know until today: sand casting actually still accounts for over 40% of total metal casting revenue"

I didn't know this either! Garage type manufacturing solutions (3d printing, bench top CNC) are enabling people to start-up with minimal capital. Sand casting / investment casting can be added to that list.