👋 Hey everyone—we had the chance to sit down with the founder of a startup using reinforcement learning in PCB design, and it turned into a really interesting conversation about his journey from post-Soviet Ukraine to building his own company. Full disclosure, they’re also a sponsor, but this conversation was too good not to share. The style’s a little different from the usual format, hope you like it!

Great founders often start by scratching their own itch. Sergiy started by answering a simple question: what’s the job of a PCB? To perfectly replicate a schematic. He’s the CEO of Quilter, a startup using AI to automate circuit board layout directly from schematics. We talk about what's broken in traditional PCB design, the landscape of existing “co-pilot” tools, and how Sergiy convinced his first investor to write a $1M blank check to figure it out.

Tell us about your background—academically and early career at SpaceX. How did you end up here?

I was born in Ukraine three months before the Soviet Union collapsed. By the time I was six, we had already gone through three different currencies, and hyperinflation was just wild. Like, the price of dinner could literally change while you were eating it. Store shelves were empty half the time, and people were bartering for basic goods. We moved to the U.S. when I was ten—super unexpected. I didn’t speak any English, and suddenly, I was just here.

Engineering was always in my orbit. My grandfather was an aeronautics engineer—part of the old-school Soviet aerospace tradition. Yuri Gagarin, Soviet engineering feats, all that stuff was a big part of my upbringing. He had this methodical, precise way of thinking about technology, and that really shaped how I approached problem-solving later on.

I was always building things—robots, circuits, whatever I could get my hands on. One of my first real projects was an attempt at an indoor GPS system. I was working with robotics and realized, wait, GPS doesn’t work indoors. That sucked, so I started thinking about how to solve it. My first attempt used ultrasound—I built a system in a physics class that sent sonar pulses and measured the return time. But then I hit a wall because sound doesn’t travel through pockets or solid objects.

I pivoted to radio waves and ended up taking a graduate-level microwave engineering course to figure it out. Eventually, while working at SpaceX, I developed an ultra-wideband RF positioning system with sub-centimeter accuracy—better than traditional GPS. I didn’t commercialize it, which, looking back, was probably a mistake. A few years later, Apple put ultra-wideband chips in iPhones for the same purpose. Timing is everything.

For college, I triple-majored in chemistry, physics, and math. Not because I had some grand plan—more like, I knew I wanted to build things, and I figured the deeper my understanding of fundamental principles, the more adaptable I’d be. At first I was leaning toward research, maybe a PhD, but after graduating, I wanted to check out industry first. I went to the career fair and SpaceX had by far the longest line, and everyone seemed to want in. I ended up spending five years there, working on avionics and power distribution systems.

Why did you leave SpaceX to start your own company?

I always knew I wasn’t going to stay in one place my whole career. I loved my time at SpaceX, but five years in, I was ready to explore something new.

After leaving the company, I started consulting. One of those consulting gigs ended up being life-changing. I was helping an investor do due diligence on a sensor company, assessing the technical feasibility of their tech. It turned out he wasn't just evaluating the company, and after working together for a bit he just said:

“You should start a company. I’ll give you a million bucks. Go for it.”

So yeah, I had a blank check to build something—but I didn’t want to jump into just any idea. I spent the next nine months figuring out what problem was actually worth solving.

Did you explore other ideas before landing on Quilter?

The first ideas weren't about PCB design at first. The investor gave me a lot of leeway to build basically whatever I wanted. So, I spent months researching different industries, looking for a problem where AI and automation could drive real impact.

I kept coming back to my own frustrations with PCB design, especially at SpaceX. Even at one of the most advanced aerospace companies on the planet, PCB layout was still a tedious, manual process.

I thought back to my first PCB project at SpaceX. The board I designed literally burned up in my hands. I tried using an auto-router, and it was complete garbage. That was my first real "There has to be a better way" moment. And as I kept digging, I realized—traditional PCB design tools haven’t fundamentally changed in decades. AI had disrupted so many other engineering fields, but PCB layout was still stuck in the past.

That’s when it clicked: what if we could build a system that automated PCB layout entirely? Not an "AI co-pilot" that assists a human designer, but something fully autonomous—an actual AI design engine. That’s what led to Quilter.

What exactly is Quilter building?

Quilter is an AI-driven PCB layout system that completely automates design. Traditional EDA tools are still manual—you place components, route traces, enforce design rules, all by hand. Some tools have automation features, but they’re almost all half-baked.

We use reinforcement learning and computational physics to generate manufacturable, optimized PCB layouts directly from schematics. No human intervention needed. It’s not trained on past designs or human decisions—just physics and constraints. That means it doesn’t inherit bad habits or biases. It builds boards the right way, from the ground up. We’re already seeing adoption in R&D teams designing IC test boards, evaluation boards, and test fixtures. But this is just the start. AI-driven automation is transforming every industry, and PCB design is no different.

Eventually, designing a board will be as simple as writing a high-level intent, and Quilter will handle the execution.

How is your company different from other AI-assisted PCB design tools?

Most AI-assisted tools today are "co-pilots" that still require human oversight. They might help with parts of the process—suggesting placements, auto-routing traces, or even optimizing some electrical parameters—but at the end of the day, the bottlenecks are still there.

Our tool is fully autonomous, but specifically for PCB layout. We take a schematic that’s already been designed, and we handle placement and routing following your rules and constraints specifications, returning a complete, manufacturing-ready PCB layout.

We focus purely on layout, giving teams an unlimited ability to test design variations without tying up valuable engineering time. Engineers get a fully routed board instantly—faster than a human could do it—allowing them to explore more options, validate concepts earlier, and make better design choices before committing limited PCB resources. This accelerates time to market and enables more innovation while freeing both engineers and PCB designers to focus on refining the optimal board.

It’s also deterministic: Quilter generates predictable, repeatable layouts—so you’re not rolling the dice every time you run it. If you need to make a design change, you can rerun it instantly and see exactly how that impacts the layout, without introducing random variations or unexpected constraints. That level of control means R&D teams can move much faster while staying confident that their designs will work when they hit the lab.

What are some unexpected ways people are using the tool?

We’ve seen some cool use cases. One engineer used Quilter to figure out the minimum viable board size. Instead of manually optimizing, they just submitted the same design at different board sizes—extra small, small, medium, large, extra large. Quilter completed each layout, and they just picked the smallest that worked.

Another big one is treating it like a compiler. In software, you don’t wait until you’ve written every line of code before compiling. You compile constantly—test, debug, iterate. Some of our most advanced users are applying that same philosophy to hardware. They run our tool multiple times a day on incomplete schematics to check feasibility, catch mistakes early, and explore design variations. That’s huge because it prevents expensive respins down the line.

We’re also seeing SI/PI engineers use Quilter for rapid troubleshooting. Normally, if there’s a signal integrity issue, an SI/PI expert runs a simulation, suggests fixes, and hands it back to a PCB designer, who then has to redo the board. Now, SI/PI experts can just tweak constraints themselves, re-run Quilter, and get an updated layout instantly—cutting out the back-and-forth.

Then, there’s the fun stuff—mechanical keyboards, vintage computers, even a snowman-shaped PCB someone made for holiday decorations.

Where do you see the company in the next few years?

Right now, we’re focused on removing bottlenecks in R&D and test boards. But long-term, Quilter is going to redefine PCB design at scale.

We’re already seeing AI-driven automation disrupt manufacturing, software, and semiconductor design. PCB layout is next. In three years, Quilter will be the industry-standard AI design engine—integrated into MilAero, high-tech manufacturing, and consumer electronics workflows.

The future of PCB design isn’t manual. Engineers will describe what they need, and AI will generate the design.

Just like software evolved from low-level assembly to high-level programming, PCB design is heading in the same direction.

What's your favorite interview question to ask?

I always ask "why?"—a lot. Not in an annoying way, but to see how deep someone really understands something. The best candidates can explain things at multiple levels. If I ask why enough times and they keep giving me clear, thoughtful answers, I know they actually get it. And if they don’t know? That’s fine—what matters is whether they admit it. The worst thing is when someone tries to BS their way through.

I’m looking for curiosity and honesty. If you’ve never thought about something deeply before, just say so. But if you have thought about it, I want to see how far down the rabbit hole you’ve gone. That’s how I figure out if someone’s the kind of engineer who just follows instructions, or the kind who actually wants to understand how things work at the fundamental level.

If you want to learn more: Quilter is currently in open beta—give it a try yourself! You can also request an evaluation for your company here.

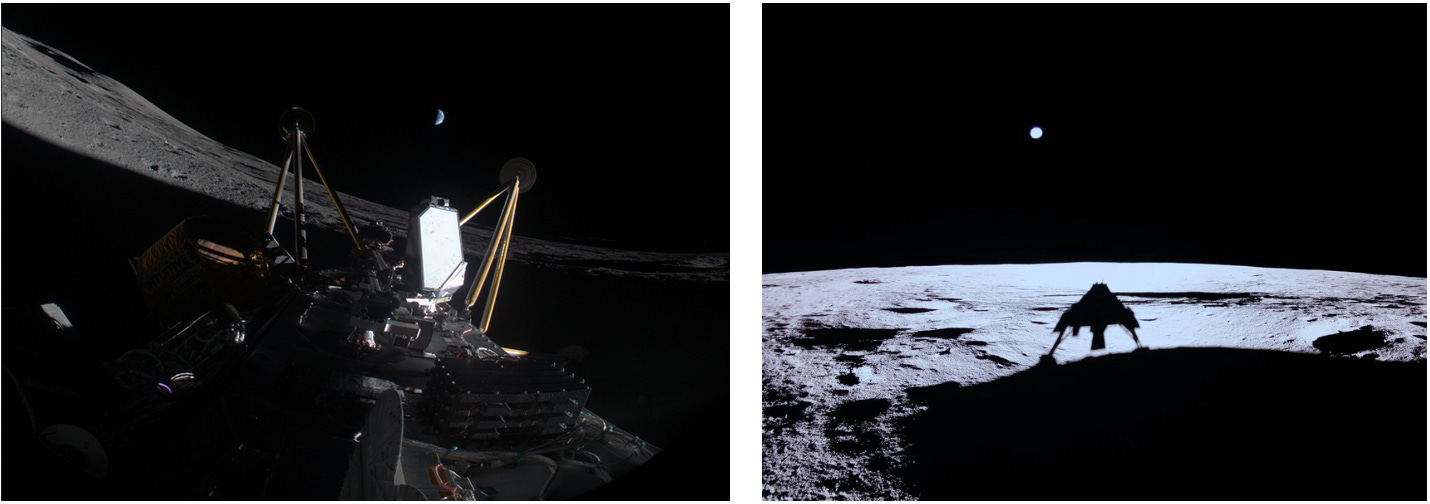

In the News: Lunar Landings & Starship Flight Test 8

Lunar Landings: This week had two attempts at lunar landings as part of NASA's commercial lunar payload services (CLPS) program, where private companies (rather than NASA) are now building, operating, and landing spacecraft on the Moon. 6 more missions are slated under CLPS through 2026.

On Tuesday, Firefly Aerospace's Blue Ghost lunar lander successfully touched down upright in Mare Crisium, delivering 10 NASA experiments.

On Thursday, Intuitive Machines' Athena lander wasn't so lucky—after touching down near the lunar south pole, it tipped onto its side and stopped communicating just a day later.

Starship Test Flight 8: SpaceX launched its eighth Starship test flight Thursday afternoon, aiming for a third successful booster catch and testing major upgrades to the Starship upper stage. The booster catch succeeded, but the upper stage experienced a rapid unscheduled disassembly during its ascent burn, similar to the issues faced by Ship 33 in the previous test flight. It’s still insane to fathom that we live in a world where mechanical arms on a tower can catch a ~275,000 kg rocket.

Refer Friends, Get a T-Shirt! 👕

If you like the newsletter, chances are you know a few others who would too. Refer five of them, and we’ll send you a t-shirt. No strings attached. Just a simple thank you.

Thanks for reading to the end - if you’ve enjoyed the mechanics of these insights, consider sharing this issue with a fellow enthusiast!

Some part of me thinks "wow, you're invented the auto-router." Another part of me thinks "If this works I won't be able to afford it, and there will be no point in routing boards by hand–which I really enjoy."

More generally, where does this all end? Sure, one can argue art for art's sake should only be made by people. However, I consider good engineering to be a functional art and an incredibly creative pursuit in many instances. Will much of this pursuit go to the wayside because at the end of the day what really matters is if something works well?

I wasn't aware that the prevailing feeling of layout is 'pain'; I always found it to be the most enjoyable bit! But I suppose that in order to raise VC money it *must* be framed as painful. Sigh.