Why So Many Startups Fail

Weekend Wire #42

👋 Happy Saturday! This week’s highlights include an analysis of why so many consumer hardware startups fail, a look at the state of hardware agencies and their economics, and a video unpacking the concept of the “march of nines” in relation to autonomous driving.

P.S. We’re hosting an online workshop on factory site selection (think playbooks on how high-growth manufacturers and startups decide where to build) on 11/06. And if you’re in San Francisco, we’re running it back with another happy hour in SF on 11/13!

Interesting Chart: Why So Many Hardware Startups Fail

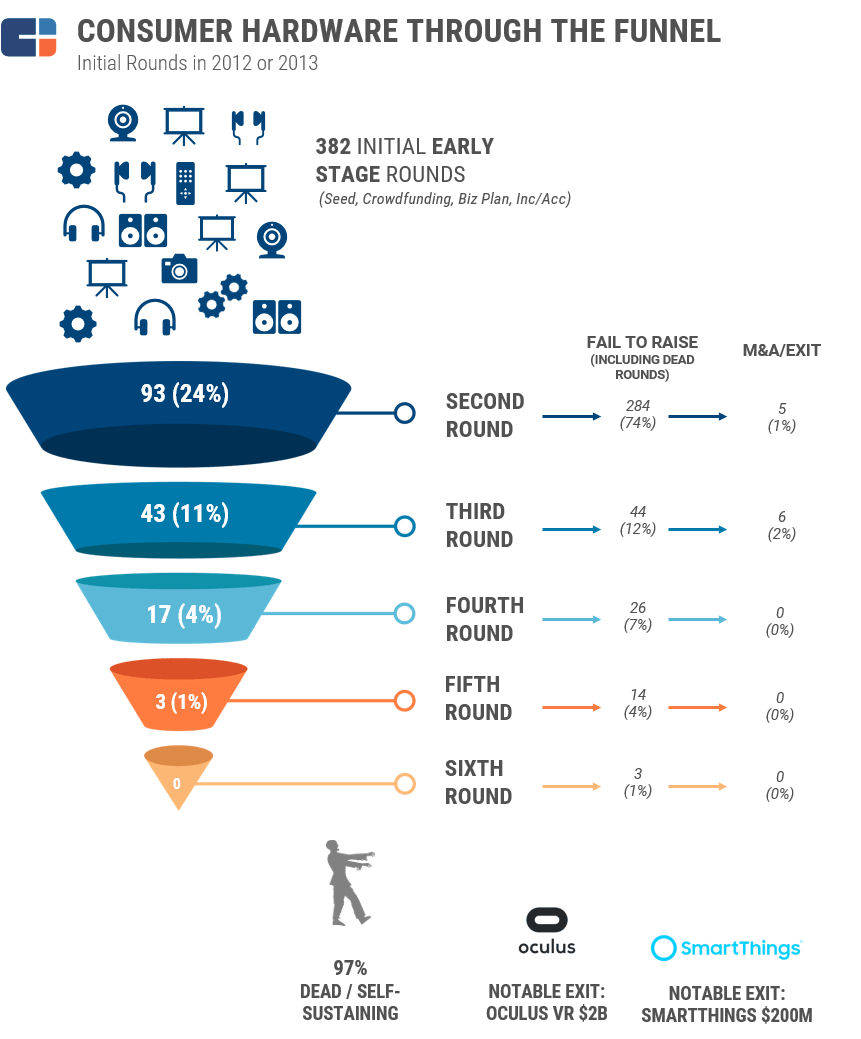

From a 2017 CB Insights report, the brutal math of consumer hardware startups is that 97% of all startups fail. Back then, the funding zeitgeist was IoT and wearables, specifically the ‘smart’ everything era of the 2010s. A few cycles later the focus moved between autonomy—self-driving cars, industrial deployments, and now humanoids—picked up climate tech along the way, and settled into today’s focus on defense and space. It’s an interesting snapshot in time and while the context has changed, the underlying lessons are worth understanding:

Crowdfunding works best as a pre-order tool, not a financing strategy. Over half (56%) of the 382 startups analyzed raised their first funds on Kickstarter or Indiegogo, with a median raise of $210K. Generally just enough capital for concept designs and early prototypes.

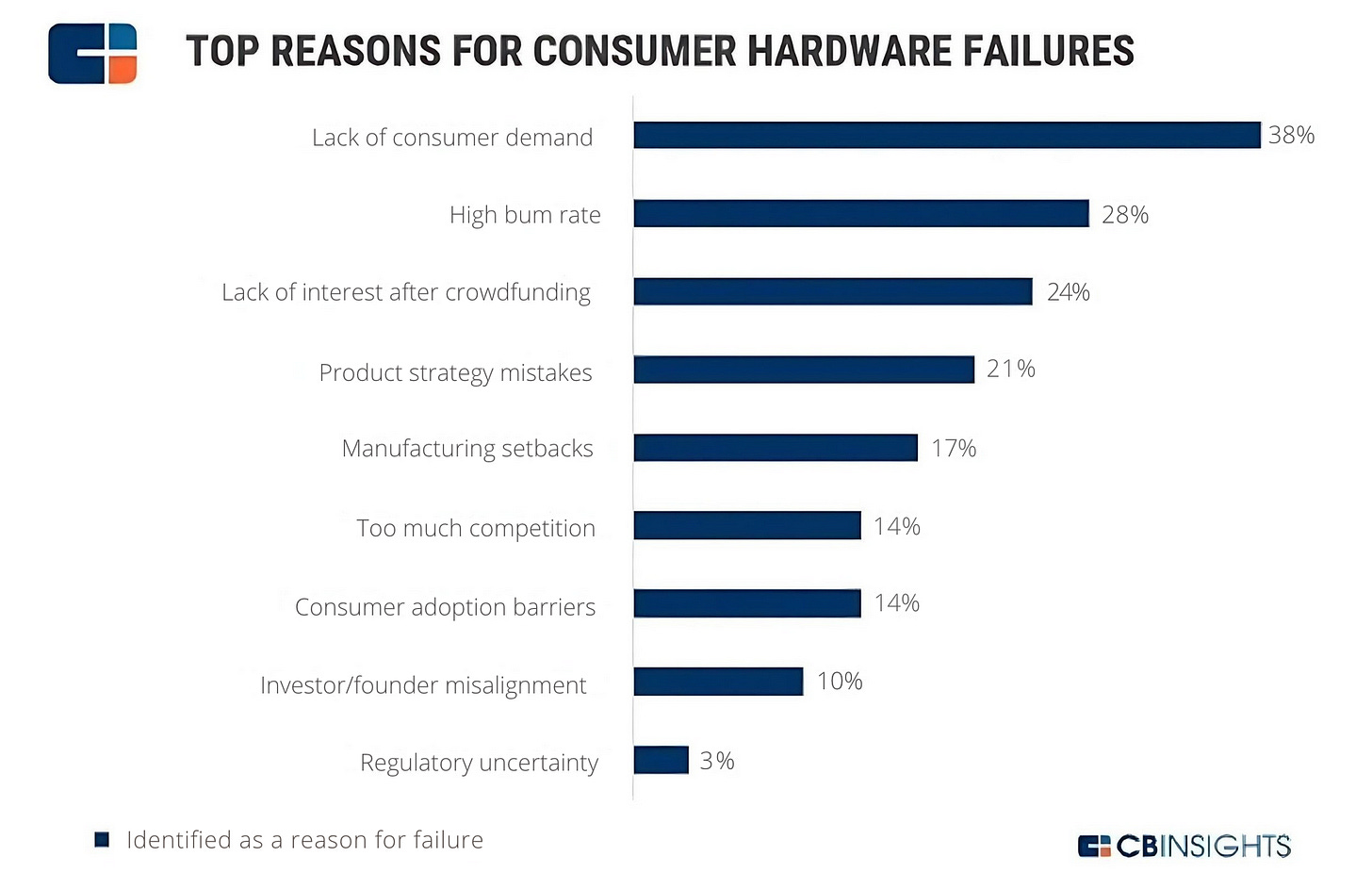

Limited release ≠ scalable business. Many teams raised enough to reach a pilot or limited release, only to find there wasn’t a large enough market to justify scaling or a follow-on raise. Lack of sustained demand was the single biggest reason for failure.

The top four reasons for failure were: (1) lack of consumer demand, (2) high burn rate, (3) loss of interest after crowdfunding, and (4) product strategy mistakes.

And for a reminder of how far off the rails hype can go, here’s a Vogue review of Juicero, the $699 internet-connected juicer startup:

There have been moments when I’ve felt, with palpable certainty, that time has slipped into the future: the advent of the Hoverboard, the invention of the Venmo payment, the first time my fingerprint unlocked an iPhone. Watching Doug Evans make me a glass of green juice last week with a Juicero—his new invention launching today in California, powered by an industrial-strength pressing mechanism and more than $100 million in Silicon Valley venture capital—was every bit as surreal.

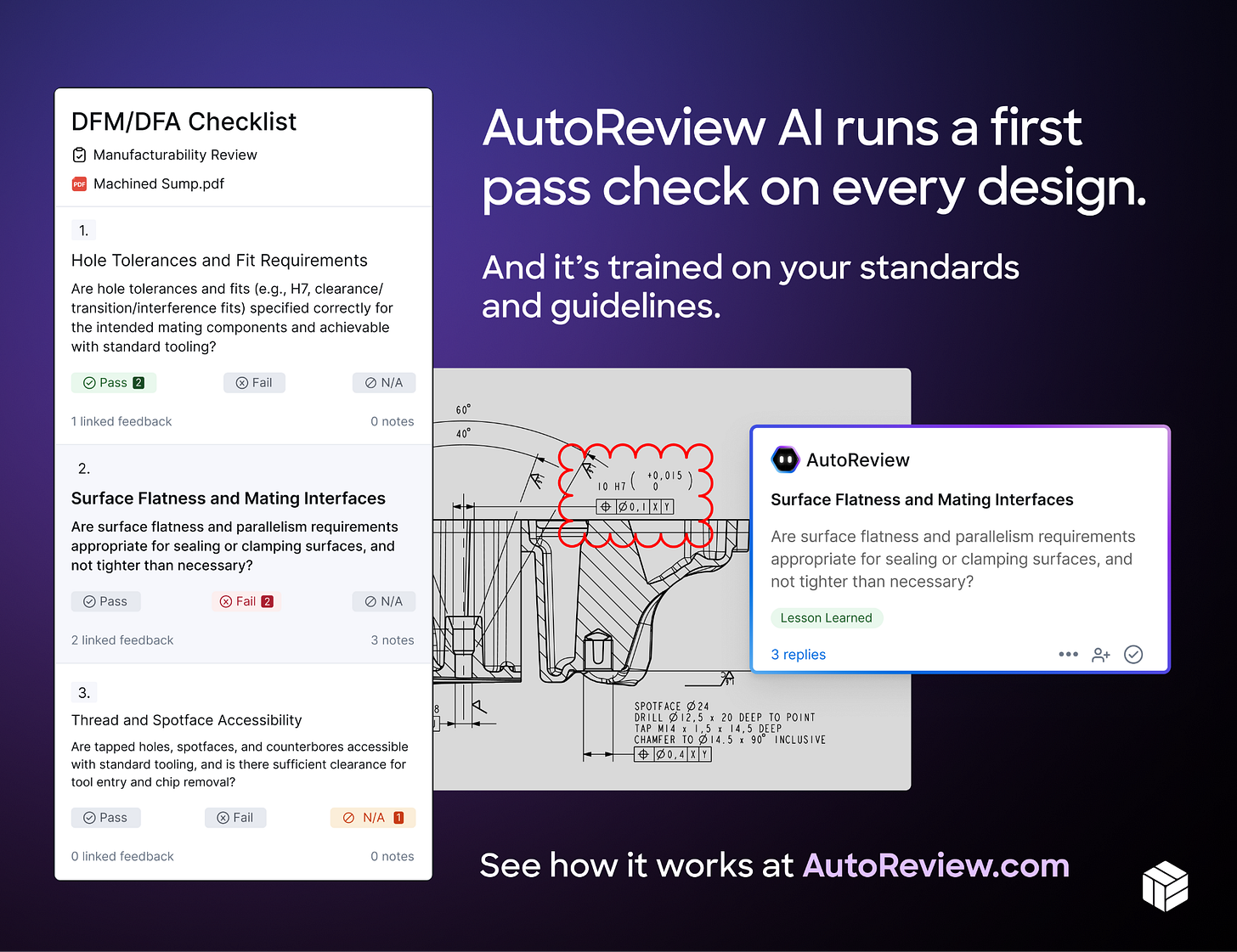

AutoReview: Your AI Peer Checker for Designs

CoLab’s AutoReview doesn’t just point out design errors. It can connect each issue to the right standard or internal guideline, so engineers know exactly how to fix it. No more chasing experts or digging through outdated PDFs. Teams apply their company’s design standards automatically, catching errors early and understanding the “why” behind every AI suggestion. Join the waitlist here.

Interesting Report: The Hardware Agency Rolodex

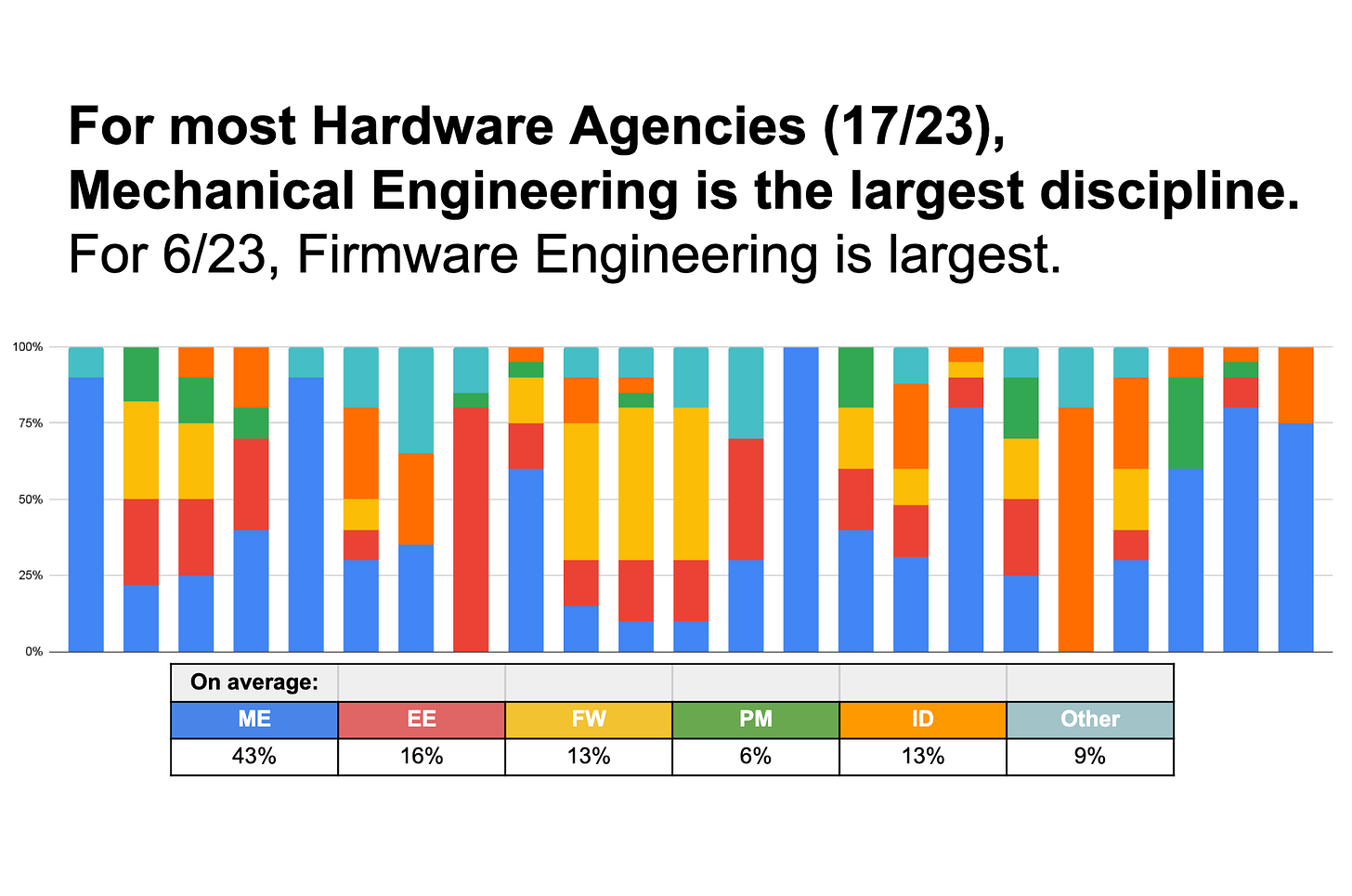

On the same theme, Sean McBride’s Hardware Agency Rolodex & Report is a look at the state of the hardware consultancy industry. These are firms that design, prototype, and sometimes build products on behalf of other companies—essentially fractional engineering teams that fill the gaps early in development.

Most operate in consumer and medical markets, with a few branching into aerospace. In 2024, projected revenues ranged from $440K to $25M, with revenue per employee between $54K and $545K. Average profit margins hovered around 11%, and most contracts remain below $500K.

From our experience, agencies work best for tightly scoped projects and core development should always stay in-house. Incentives matter; no contractor has the same urgency or risk tolerance as the team whose future depends on shipping the product. The full list of participants polled are listed here.

Interesting Video: The Long Road to Full Autonomy

In a recent podcast, Andrej Karpathy (founding lead of Tesla’s Autopilot vision team) explained why self-driving has taken over a decade to mature and still isn’t finished. One idea that stood out was the “march of nines,” a way to describe progress in safety-critical systems where the cost of failure is too high:

“It’s a march of nines, and every single nine is a constant amount of work. So every single nine is the same amount of work. When you get a demo and something works 90% of the time, that’s just the first nine. Then you need the second nine, a third nine, a fourth nine… While I was at Tesla for five years, I think we went through maybe two or three nines of iteration, but there are still more nines to go. That’s why these things take so long.”

Manufacturing & Startup News

More leftovers from our weekly research:

YASA set a 59 kW/kg power density record in its 12.7 kg axial-flux motor prototype, delivering 750 kW peak power for next-gen electric propulsion systems.

Dominion Dynamics raised $4M in pre-seed funding to link distributed sensors into a data-sharing mesh for Arctic surveillance.

Oureon Technologies raised $3.5M in pre-seed funding to prototype its real-time communication layer enabling safe coordination between manned and unmanned aircraft. Drone traffic is projected to outnumber conventional flights 8×.

United States Antimony Corporation began mining operations at Montana’s Stibnite Hill site, trucking ore to its smelter to support U.S. defense and manufacturing supply chains.

Tools From Our Sponsors

Flow – Agile requirements management platform for complex systems.

Jiga – Custom parts at digital speed, with trusted shop access.

Zenode – Free AI-powered search engine for electronic components. A smarter, faster alternative to part catalogs like Digi-Key.

Access Every Link We’ve Ever Shared 🎞️

Refer three friends to Hardware FYI and unlock our full archive.

Missed an issue? Hunting for that one link? Every tool, guide, and article we’ve ever shared is in here.

Thanks for reading to the end - if you’ve enjoyed the mechanics of these insights, consider sharing this issue with a fellow enthusiast!

16,000+ engineers, founders, and operators read this newsletter. If you want to reach them, get in touch.

Getting from prototype to volume is the real make-or-break time for EVs. If you look at the US, only Tesla, Rivian and Lucid have made the leap. Dozens of companies revealed concepts, show cars and prototypes, but stumbled getting to any sort of volume.

The Capex for volume production is huge, persuading suppliers to work with you is challenging, and it is where all those design decisions come back to haunt you, as you figure out how to assemble it all together at 10-20 jobs an hour for a premium EV.

Kitchen gadgets are my favorite!

Used to be on late night TV commercials, some even special long run like a 12 minute short story